Understanding the Importance of Plastic Granulator Machines for Efficient Recycling

Release Time:

Aug 08,2025

Plastic granulator machines are essential tools in the recycling process, particularly in the management of plastic waste. These machines are designed to break down large plastic materials into smaller granules, making it easier for manufacturers to reuse the materials in new products. The operation of a plastic granulator typically involves feeding plastic waste into the machine, where it is cut,

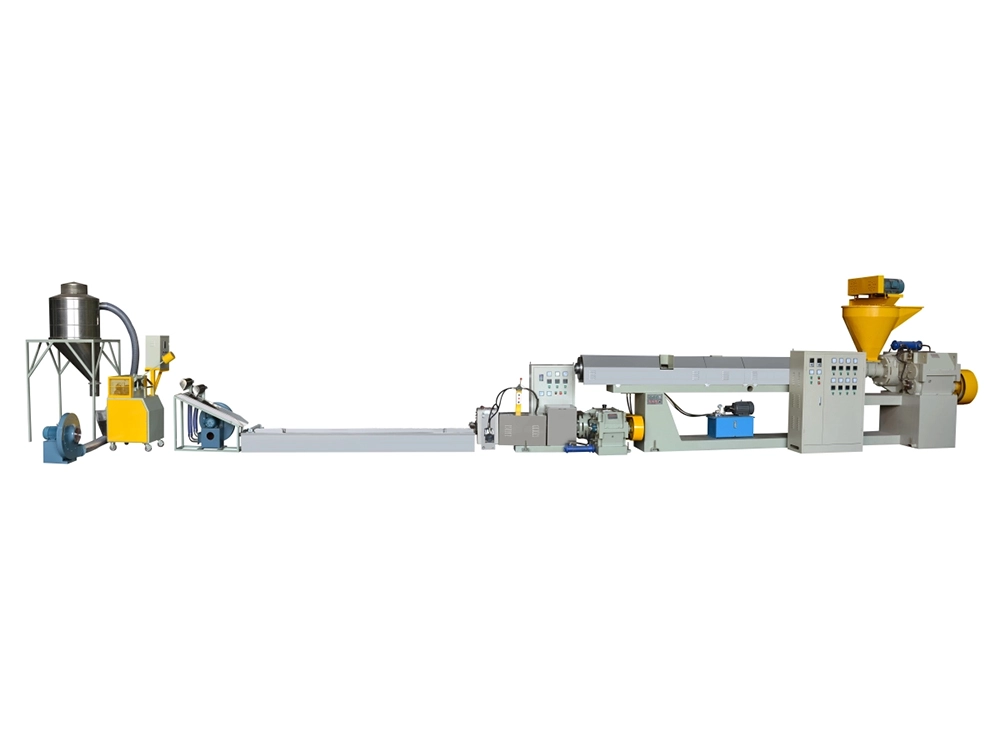

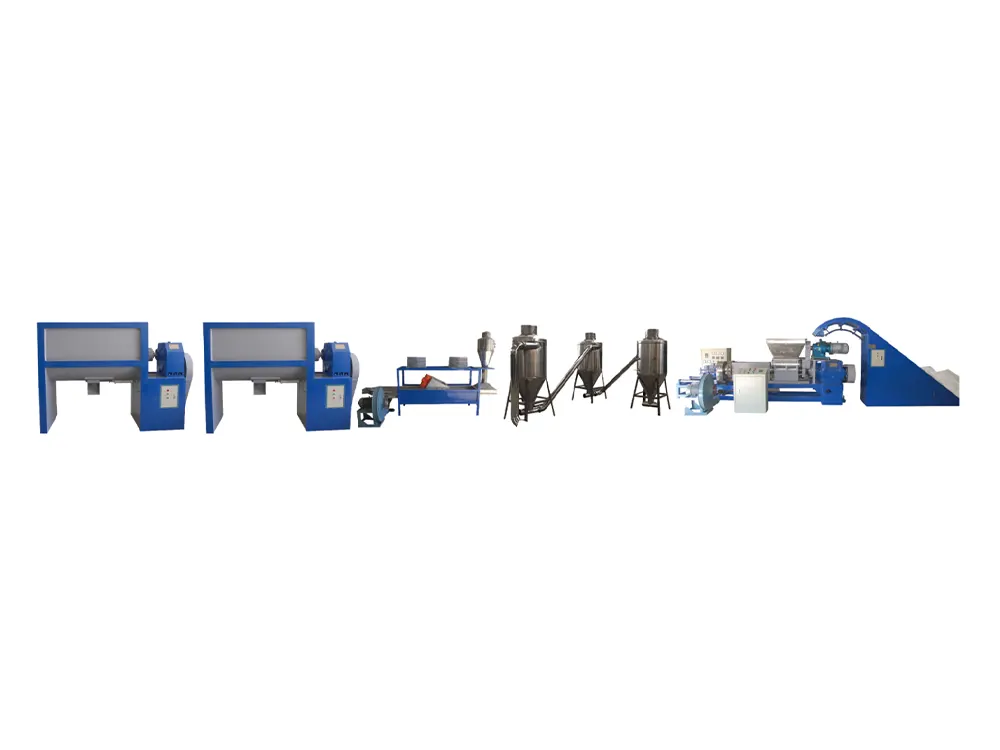

Plastic granulator machines are essential tools in the recycling process, particularly in the management of plastic waste. These machines are designed to break down large plastic materials into smaller granules, making it easier for manufacturers to reuse the materials in new products. The operation of a plastic granulator typically involves feeding plastic waste into the machine, where it is cut, ground, and processed into uniform granules. This transformation not only enhances the material's usability but also significantly reduces the volume of waste, contributing to a more sustainable environment.

One of the primary advantages of using plastic granulator machines is their efficiency in processing different types of plastics. Whether the plastic is rigid or flexible, these machines can handle various forms, including bottles, containers, and even industrial plastic scrap. This versatility allows companies to streamline their recycling operations, ensuring that a broader range of materials can be repurposed effectively.

Moreover, the granulation process helps to maintain the quality of the recycled material. By producing uniform granules, manufacturers can ensure that the end product meets quality standards required for new plastic items. This consistency is vital, as it minimizes variability in the production process and enhances the overall performance of recycled plastics in applications ranging from packaging to automotive parts.

In addition to their operational efficiency, plastic granulator machines also contribute to cost savings. By recycling plastic waste, companies can reduce their reliance on virgin materials, which are often more expensive and subject to market fluctuations. The ability to reprocess plastic into usable granules can result in significant savings over time, making these machines an attractive investment for businesses focused on sustainability and cost-effectiveness.

Furthermore, the integration of advanced technologies in modern plastic granulator machines has improved their performance and ease of use. Features such as automated feeding systems, adjustable cutting speeds, and real-time monitoring of processing conditions enhance operational efficiency and reduce downtime. These technological advancements not only optimize the recycling process but also minimize the maintenance and repair needs, ensuring that the machines operate at peak performance.

In conclusion, plastic granulator machines are vital components of the recycling industry, enabling efficient processing of plastic waste into reusable materials. Their ability to handle various types of plastics, maintain material quality, and provide cost savings makes them essential for businesses committed to sustainability. By investing in these machines, companies can contribute to a circular economy while improving their operational efficiency and profitability.

One of the primary advantages of using plastic granulator machines is their efficiency in processing different types of plastics. Whether the plastic is rigid or flexible, these machines can handle various forms, including bottles, containers, and even industrial plastic scrap. This versatility allows companies to streamline their recycling operations, ensuring that a broader range of materials can be repurposed effectively.

Moreover, the granulation process helps to maintain the quality of the recycled material. By producing uniform granules, manufacturers can ensure that the end product meets quality standards required for new plastic items. This consistency is vital, as it minimizes variability in the production process and enhances the overall performance of recycled plastics in applications ranging from packaging to automotive parts.

In addition to their operational efficiency, plastic granulator machines also contribute to cost savings. By recycling plastic waste, companies can reduce their reliance on virgin materials, which are often more expensive and subject to market fluctuations. The ability to reprocess plastic into usable granules can result in significant savings over time, making these machines an attractive investment for businesses focused on sustainability and cost-effectiveness.

Furthermore, the integration of advanced technologies in modern plastic granulator machines has improved their performance and ease of use. Features such as automated feeding systems, adjustable cutting speeds, and real-time monitoring of processing conditions enhance operational efficiency and reduce downtime. These technological advancements not only optimize the recycling process but also minimize the maintenance and repair needs, ensuring that the machines operate at peak performance.

In conclusion, plastic granulator machines are vital components of the recycling industry, enabling efficient processing of plastic waste into reusable materials. Their ability to handle various types of plastics, maintain material quality, and provide cost savings makes them essential for businesses committed to sustainability. By investing in these machines, companies can contribute to a circular economy while improving their operational efficiency and profitability.

Related Blog