What to Consider When Upgrading Your Plastic Granulator Machine: Essential Insights for Enhanced Performance

Release Time:

Aug 03,2025

What to Consider When Upgrading Your Plastic Granulator Machine Upgrading your plastic granulator machine is a significant decision that can have far-reaching effects on your production capabilities and operational costs. Whether you are aiming to enhance the quality of your output, increase efficiency, or reduce energy consumption, there are numerous factors to consider. This guide provides detai

What to Consider When Upgrading Your Plastic Granulator Machine

Upgrading your plastic granulator machine is a significant decision that can have far-reaching effects on your production capabilities and operational costs. Whether you are aiming to enhance the quality of your output, increase efficiency, or reduce energy consumption, there are numerous factors to consider. This guide provides detailed insights into the vital elements that influence your decision-making process when upgrading your plastic granulator machine.

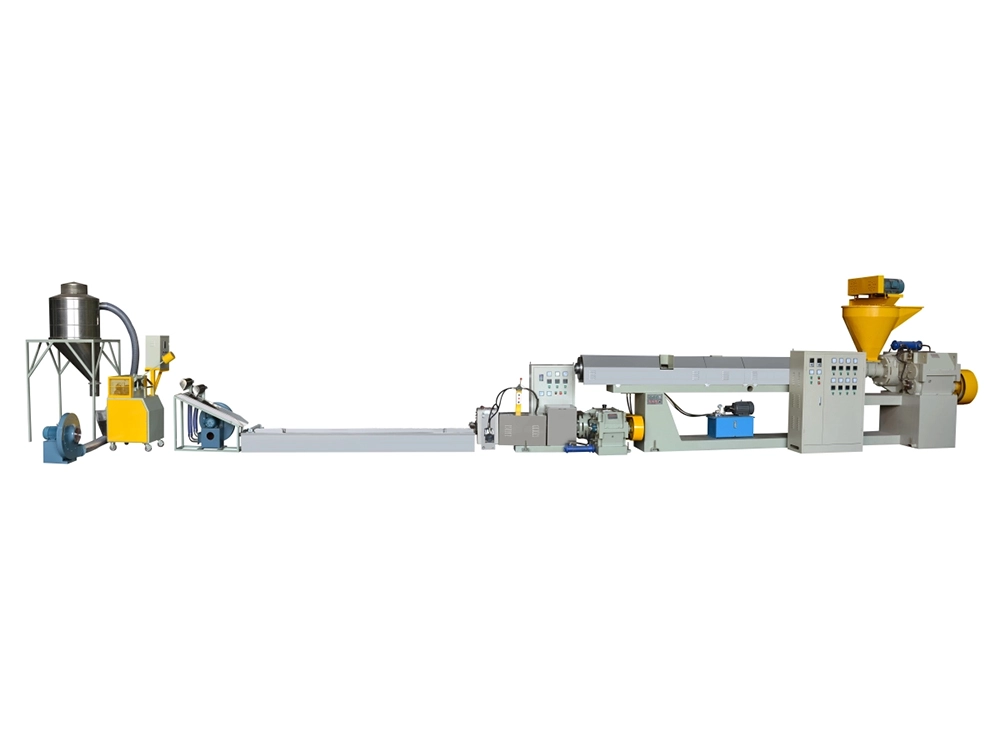

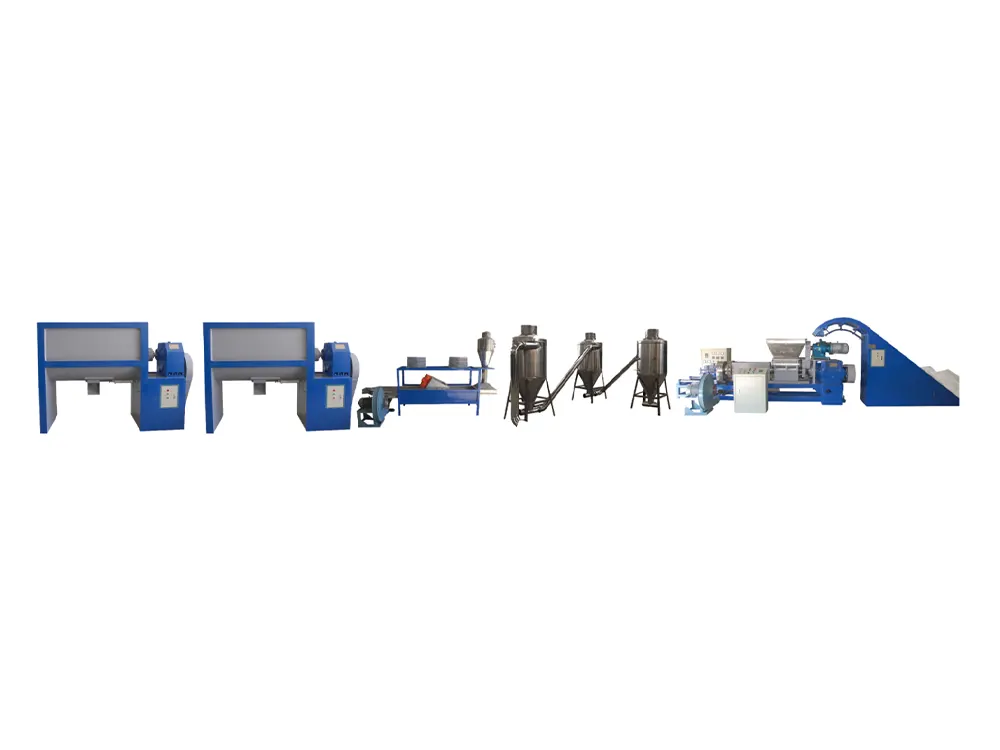

A Comprehensive Overview of Plastic Granulator Machines

Before diving into the considerations for upgrading, it is essential to understand what plastic granulator machines are and how they function. These machines play a crucial role in recycling processes, breaking down plastic waste into smaller granules that can be reused in manufacturing.

Understanding the Functionality of Granulators

Plastic granulators operate by cutting plastic materials into small pieces, enhancing their processability in subsequent stages. These machines are designed to handle various types of plastics, ensuring versatility in recycling operations. Their efficiency directly impacts the quality of the final product, making it imperative to keep them updated and well-maintained.

The Importance of Upgrading Your Granulator

Upgrading your plastic granulator machine can lead to several benefits, including improved efficiency, reduced energy consumption, better quality of output, and lower maintenance costs. As technology advances, older machines may become less effective, making upgrades necessary to stay competitive in the market.

Key Factors to Consider When Upgrading

When upgrading your plastic granulator machine, several key factors should guide your decision. These factors will ensure that the upgrade aligns with your operational goals and enhances overall productivity.

1. Evaluate Your Production Needs

Understanding your specific production requirements is fundamental. Consider the following aspects:

Type of Plastic Materials

Different plastics require different cutting methods and settings. Assess the types of materials you primarily handle. Upgrading to a granulator that specializes in your specific applications can yield better results.

Granulation Rate

Estimate the volume of material that needs processing per hour. Upgrading to a machine with a higher granulation rate can significantly increase your output and operational efficiency.

Desired Granule Size

The size of the granules impacts the quality of the final product. Ensure that any new machine can produce the sizes you require for your production needs.

2. Technological Advancements

Staying updated with the latest technology is crucial for any manufacturing process. Consider the following technological features when upgrading:

Automation Capabilities

Modern granulators often come with advanced automation features that enhance precision and reduce manual intervention. This can lead to increased efficiency and decreased operational errors.

Energy Efficiency

Energy-efficient machines can save significant costs in the long run. Look for models that offer lower energy consumption without compromising performance.

Noise Reduction Technology

Noise pollution can be a concern in industrial settings. Upgrading to a machine with noise reduction features can lead to a more comfortable working environment.

3. Quality of Components

The longevity and performance of your granulator are influenced by the quality of its components. When evaluating potential upgrades, consider:

Blade Material and Design

High-quality, durable blades can maintain performance over time and reduce the frequency of replacements. Investigate the materials used in the blades and their design, as these factors significantly affect the granulation process.

Motor Efficiency

The motor is the heart of the granulator. A more efficient motor can provide better performance and longevity, so look for machines with reliable motor specifications.

4. Maintenance and Support Services

An often-overlooked aspect of upgrading is the ongoing maintenance needs and support services available for the new machine. Consider the following:

Ease of Maintenance

Choose a granulator that is easy to maintain. Features that simplify cleaning and blade replacement can save time and costs in the long run.

Availability of Spare Parts

Ensure that spare parts for the new machine are readily available. Long lead times for parts can lead to extended downtimes.

Technical Support

Reliable technical support from the manufacturer or supplier can significantly ease the transition to a new machine. Check for available service agreements that offer timely support.

5. Budget Considerations

While it is tempting to go for the cheapest option, consider the following budget-related factors carefully:

Initial Investment vs. Long-term Savings

Assess the total cost of ownership, including energy savings and reduced maintenance costs over time. An efficient machine may have a higher upfront cost but can save you money in the long term.

Financing Options

Investigate financing options available for purchasing new machinery. Some manufacturers offer leasing options that can alleviate the financial burden of a significant upfront investment.

Benefits of Upgrading Your Plastic Granulator Machine

Understanding the benefits of upgrading can provide clarity on the importance of making this investment. Here are some of the significant advantages:

Increased Efficiency

Upgrading to a modern granulator can lead to enhanced processing speeds, reduced downtime, and a more streamlined workflow, all contributing to increased overall efficiency.

Improved Quality of Output

A new granulator can produce more consistent granule sizes and better quality materials, enhancing the overall quality of your finished products.

Cost Savings

Although the initial investment may be higher, the reduction in energy costs, maintenance expenses, and waste can lead to significant savings over time.

Environmental Impact

Modern granulators often operate more efficiently and with less waste, contributing to a lower environmental footprint. This is increasingly important as sustainability becomes a key concern for businesses.

FAQs About Upgrading Plastic Granulator Machines

1. How often should I consider upgrading my plastic granulator machine?

You should evaluate your machine every few years, especially if you notice a decline in performance, increased maintenance costs, or if your production needs have changed.

2. What are the signs that my granulator needs an upgrade?

Signs include frequent breakdowns, increased energy bills, inconsistent granule sizes, and changes in your production requirements.

3. Can I upgrade specific components instead of the entire machine?

Yes, many granulators allow for component upgrades, such as blades or motors, which can enhance performance without the need for a full replacement.

4. What should I look for in a supplier when upgrading my granulator?

Look for suppliers who offer reputable brands, provide excellent customer support, and have a good track record in the industry.

5. How can I ensure a smooth transition to a new granulator machine?

Proper planning, training for staff, and support from the manufacturer can facilitate a seamless transition and minimize disruptions in production.

Conclusion

Upgrading your plastic granulator machine is a critical decision that can significantly influence your recycling operations. By evaluating your production needs, embracing technological advancements, and considering maintenance and budget factors, you can make informed choices that enhance efficiency and output quality. The benefits of an upgraded machine extend beyond immediate operational improvements, encompassing long-term cost savings and reduced environmental impact. As you consider your options, ensure that you select a solution that aligns not only with your current needs but also positions you for future growth and sustainability in an ever-evolving industry.

Related Blog