Maximizing Your Investment in Nylon Recycling Machines: A Comprehensive Guide

Release Time:

Jul 24,2025

Getting the Most Out of Your Nylon Recycling Machine Investment Table of Contents Understanding Nylon Recycling Machines Benefits of Nylon Recycling Choosing the Right Nylon Recycling Machine Optimal Installation and Setup Efficient Operational Practices Maintenance and Technical Support Cost-Effectiveness and ROI Future Trends in Nylon Recycling Conclusion FAQs Understanding

Getting the Most Out of Your Nylon Recycling Machine Investment

Table of Contents

- Understanding Nylon Recycling Machines

- Benefits of Nylon Recycling

- Choosing the Right Nylon Recycling Machine

- Optimal Installation and Setup

- Efficient Operational Practices

- Maintenance and Technical Support

- Cost-Effectiveness and ROI

- Future Trends in Nylon Recycling

- Conclusion

- FAQs

Understanding Nylon Recycling Machines

Nylon recycling machines play a pivotal role in the sustainable management of waste materials. These advanced machines are designed specifically to process nylon waste, transforming it into reusable raw materials that can be reintroduced into the production cycle. Understanding how these machines operate is fundamental for any company looking to maximize their investment.

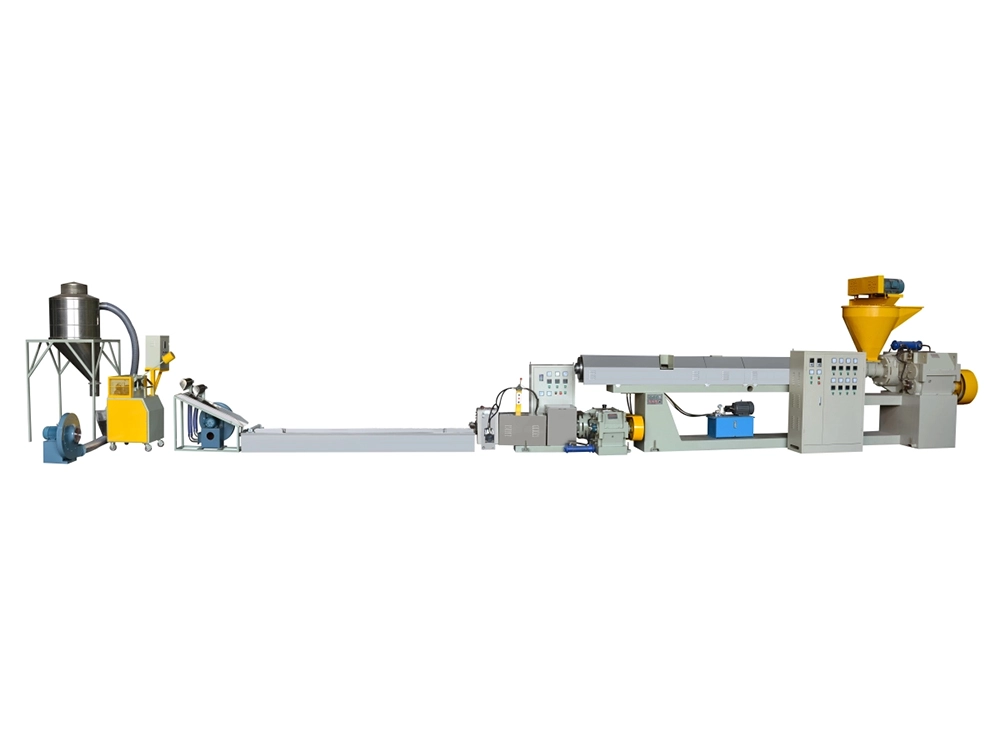

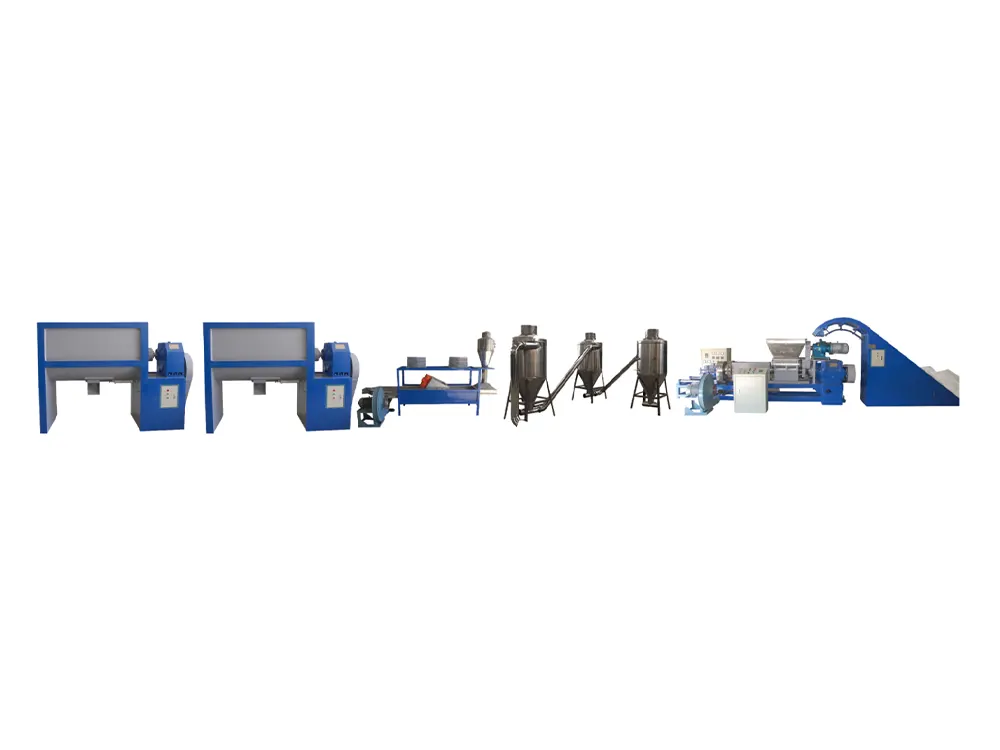

The core components of nylon recycling machines include shredders, granulators, and extruders. Each component serves a specific purpose in the recycling process. Shredders break down larger nylon items into smaller fragments, which are then ground by granulators into uniform pieces. Finally, extruders melt and reform the granulated nylon into new products or pellets. Familiarity with these components allows operators to optimize each stage of the recycling process.

Benefits of Nylon Recycling

Investing in a nylon recycling machine offers numerous benefits. Not only does it contribute to environmental sustainability by reducing landfill waste, but it also has significant economic advantages. Here are some key benefits:

1. **Cost Savings**: Recycling nylon significantly reduces the need for virgin materials, leading to substantial cost savings over time.

2. **Increased Sustainability**: By recycling nylon, companies can lower their carbon footprint and demonstrate a commitment to environmental responsibility.

3. **Versatile Applications**: Recycled nylon can be used in a variety of products, from textiles to engineering plastics, thus expanding market opportunities.

4. **Enhanced Brand Image**: Companies that embrace sustainable practices often enjoy improved brand loyalty and customer satisfaction.

5. **Regulatory Compliance**: Many regions have stringent regulations regarding waste management. Investing in recycling equipment helps businesses comply with these laws.

Choosing the Right Nylon Recycling Machine

Selecting the appropriate nylon recycling machine is crucial for maximizing your investment. Here are several factors to consider:

1. **Production Capacity**: Assess your production needs to choose a machine that meets your output requirements.

2. **Material Types**: Ensure the machine can handle the specific types of nylon waste you intend to process, such as nylon 6 or nylon 66.

3. **Energy Efficiency**: Look for machines designed to minimize energy consumption, as this can lead to lower operational costs.

4. **Space Requirements**: Evaluate the available space in your facility to ensure the new equipment fits seamlessly into your workflow.

5. **Supplier Reputation**: Choose a reputable supplier known for quality machines and customer support.

Optimal Installation and Setup

Proper installation and setup of your nylon recycling machine are essential for optimal performance. Here are some best practices:

1. **Professional Installation**: Engage professionals to ensure that the machine is installed correctly and complies with safety regulations.

2. **System Integration**: Ensure that the recycling machine integrates smoothly with existing systems, including conveyor belts and packaging equipment.

3. **Training for Operators**: Provide comprehensive training for your team to ensure they are familiar with the machine’s operations and safety protocols.

4. **Calibration**: Regularly calibrate the machine to maintain efficiency and product quality.

Efficient Operational Practices

Maximizing the efficiency of your nylon recycling machine involves adopting specific operational practices:

1. **Regular Monitoring**: Keep an eye on production metrics to identify any inefficiencies promptly.

2. **Standard Operating Procedures (SOPs)**: Develop and enforce SOPs to streamline operations and ensure consistency.

3. **Waste Management**: Implement a robust waste management strategy to minimize downtime due to material handling issues.

4. **Employee Engagement**: Foster a culture of continuous improvement by encouraging employees to suggest ideas for enhancing operational efficiency.

Maintenance and Technical Support

Routine maintenance is critical to prolonging the life of your nylon recycling machine. Here are some recommendations:

1. **Scheduled Maintenance**: Implement a regular maintenance schedule to check all machine components for wear and tear.

2. **Technical Support**: Establish a relationship with your machine supplier for ongoing technical support and assistance.

3. **Parts Replacement**: Keep essential spare parts on hand to reduce downtime during repairs.

4. **Training**: Regularly train staff on maintenance best practices to ensure they are equipped to handle minor issues.

Cost-Effectiveness and ROI

Understanding the financial implications of your nylon recycling machine investment is essential. To evaluate cost-effectiveness:

1. **Initial Investment vs. Long-term Savings**: Analyze the initial outlay against potential savings from reduced material costs and waste disposal fees.

2. **Return on Investment (ROI)**: Calculate your ROI by measuring the total benefits generated from recycling against the costs incurred.

3. **Market Trends**: Stay informed about market trends for recycled materials to adjust your operational strategy accordingly.

Future Trends in Nylon Recycling

The nylon recycling industry is rapidly evolving. Here are some trends to watch:

1. **Technological Advancements**: Innovations in recycling technology are improving efficiency and product quality.

2. **Increased Demand**: As sustainability becomes more critical, the demand for recycled nylon will likely grow, offering new market opportunities.

3. **Regulatory Changes**: Keep abreast of regulations that may affect recycling practices and ensure compliance to avoid penalties.

4. **Collaborations**: Partnerships between manufacturers and recyclers are becoming more common as companies seek sustainable solutions throughout their supply chains.

Conclusion

Investing in a nylon recycling machine is a strategic decision that can yield significant benefits for both the environment and your bottom line. By understanding the operation of these machines, choosing the right equipment, implementing efficient operational practices, and committing to maintenance and support, you can maximize your investment. As the industry evolves with new technologies and increasing demand for sustainability, staying informed and adaptable will be essential for continued success.

FAQs

What types of nylon can be recycled?

Nylon 6, nylon 66, and other variants can successfully be processed through recycling machines, depending on the equipment's capabilities.

How often should I perform maintenance on my nylon recycling machine?

Regular maintenance should be scheduled based on the manufacturer's recommendations, typically every six months to a year, depending on usage.

Can recycled nylon be used in food packaging?

Recycled nylon is generally not approved for direct food contact unless processed through certified methods. Always check local regulations.

What are the financial benefits of recycling nylon?

Recycling nylon can lead to reduced material costs, lower waste disposal fees, and potential government incentives for sustainable practices.

How can I increase the efficiency of my nylon recycling operations?

Implementing regular monitoring, investing in employee training, maintaining equipment, and adopting best practices for waste management can significantly enhance efficiency.

Related Blog