Unlocking the Potential of Nylon Recycling Machines: A Guide for Maintenance and Support Professionals

Release Time:

Jul 29,2025

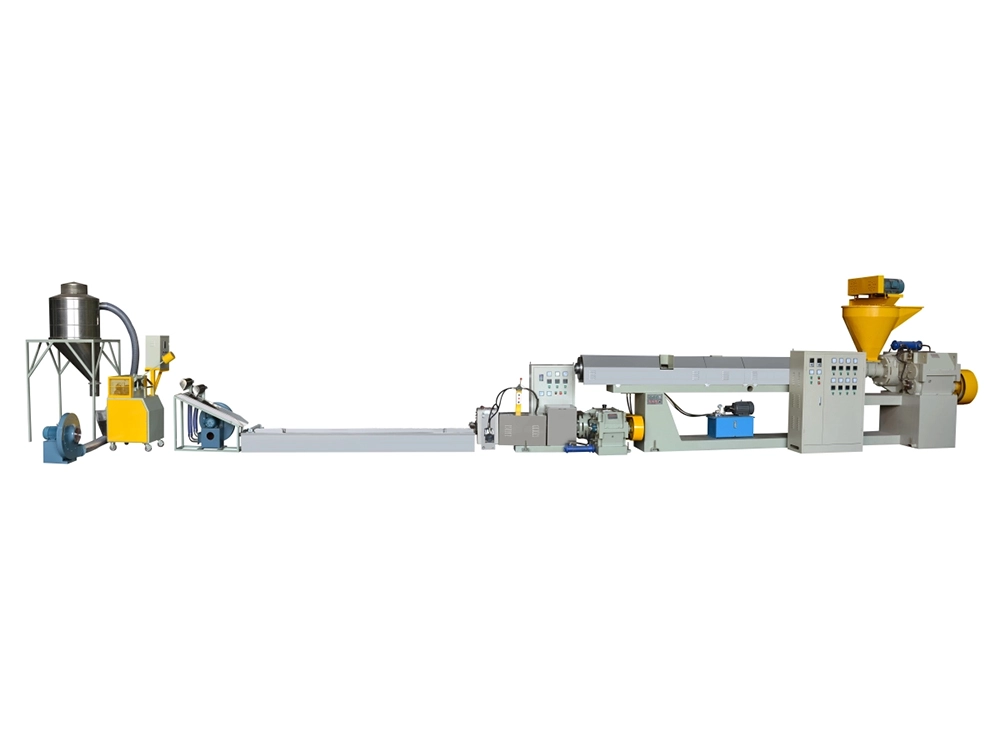

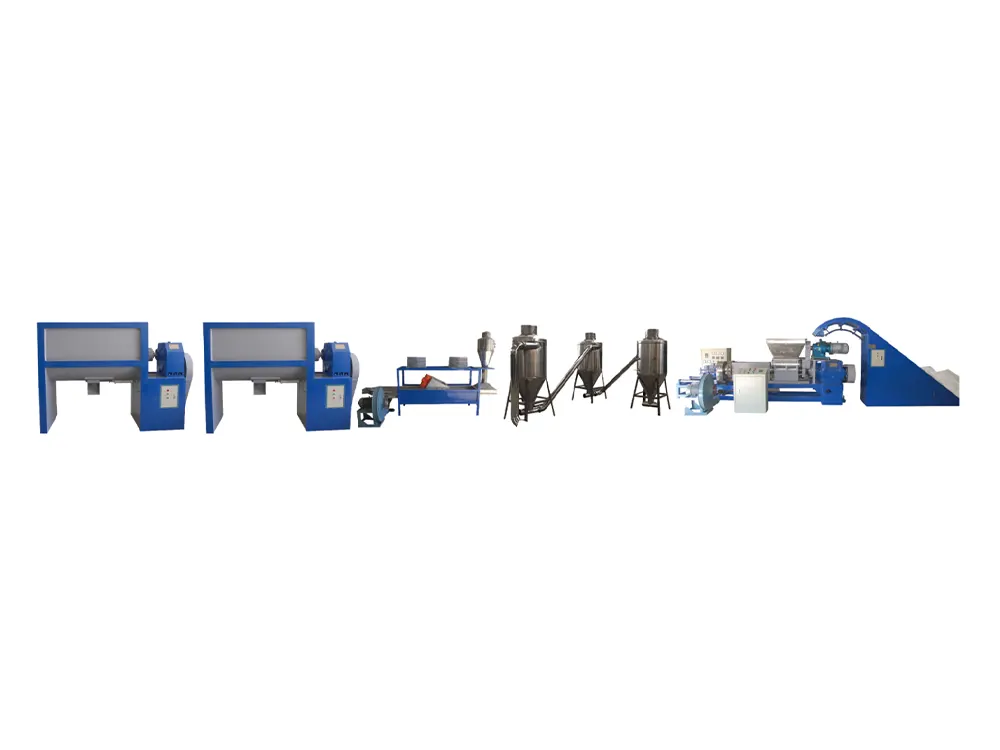

In the ever-evolving landscape of recycling technology, nylon recycling machines have emerged as vital components in the quest for sustainability. These machines are specifically designed to process waste nylon materials, transforming them into reusable raw resources. As a professional in the field of mechanical equipment repair, installation, and technical support, understanding the intricacies o

In the ever-evolving landscape of recycling technology, nylon recycling machines have emerged as vital components in the quest for sustainability. These machines are specifically designed to process waste nylon materials, transforming them into reusable raw resources. As a professional in the field of mechanical equipment repair, installation, and technical support, understanding the intricacies of these machines can significantly enhance your clients' operational efficiency and environmental compliance.

Nylon, a synthetic polymer widely used in textiles, automotive components, and industrial applications, poses unique challenges for recycling due to its complex structure. Nylon recycling machines utilize advanced technologies to break down waste nylon into smaller particles, which can then be reconstituted into new products. Various methods such as mechanical recycling, chemical recycling, and thermal recycling can be implemented depending on the specific needs and capabilities of the operation.

When it comes to the maintenance and installation of nylon recycling machines, several key aspects should be considered. First and foremost, regular maintenance is essential for ensuring optimal machine performance. This includes routine checks on mechanical components, lubrication of moving parts, and monitoring of electrical systems. Implementing a preventive maintenance schedule can help mitigate unexpected breakdowns and prolong the lifespan of the equipment.

Moreover, during the installation phase, it is crucial to assess the operational environment and ensure that the machinery is appropriately positioned and calibrated. Adequate training for operators will also enhance the efficiency of the recycling process. Operators should be well-versed in the machine's functions, safety protocols, and troubleshooting techniques to swiftly address any issues that may arise.

Additionally, understanding the specifications and capabilities of different nylon recycling machines is vital. Factors such as processing capacity, energy consumption, and output quality should be thoroughly evaluated. By offering tailored solutions based on your clients' specific needs, you can position yourself as a trusted advisor within this niche market.

As the demand for sustainable practices continues to rise, the significance of nylon recycling machines will only grow. By equipping yourself with in-depth knowledge and technical expertise in this area, you will be better prepared to support your clients in their recycling endeavors. Whether through installation, maintenance, or ongoing technical support, your services will play a pivotal role in helping organizations achieve their sustainability goals and improve their overall operational efficiency.

In conclusion, nylon recycling machines represent a substantial opportunity for service professionals. By focusing on maintenance, proper installation, and understanding their operational intricacies, you can help your clients harness the full potential of these machines, contributing to a more sustainable future.

Nylon, a synthetic polymer widely used in textiles, automotive components, and industrial applications, poses unique challenges for recycling due to its complex structure. Nylon recycling machines utilize advanced technologies to break down waste nylon into smaller particles, which can then be reconstituted into new products. Various methods such as mechanical recycling, chemical recycling, and thermal recycling can be implemented depending on the specific needs and capabilities of the operation.

When it comes to the maintenance and installation of nylon recycling machines, several key aspects should be considered. First and foremost, regular maintenance is essential for ensuring optimal machine performance. This includes routine checks on mechanical components, lubrication of moving parts, and monitoring of electrical systems. Implementing a preventive maintenance schedule can help mitigate unexpected breakdowns and prolong the lifespan of the equipment.

Moreover, during the installation phase, it is crucial to assess the operational environment and ensure that the machinery is appropriately positioned and calibrated. Adequate training for operators will also enhance the efficiency of the recycling process. Operators should be well-versed in the machine's functions, safety protocols, and troubleshooting techniques to swiftly address any issues that may arise.

Additionally, understanding the specifications and capabilities of different nylon recycling machines is vital. Factors such as processing capacity, energy consumption, and output quality should be thoroughly evaluated. By offering tailored solutions based on your clients' specific needs, you can position yourself as a trusted advisor within this niche market.

As the demand for sustainable practices continues to rise, the significance of nylon recycling machines will only grow. By equipping yourself with in-depth knowledge and technical expertise in this area, you will be better prepared to support your clients in their recycling endeavors. Whether through installation, maintenance, or ongoing technical support, your services will play a pivotal role in helping organizations achieve their sustainability goals and improve their overall operational efficiency.

In conclusion, nylon recycling machines represent a substantial opportunity for service professionals. By focusing on maintenance, proper installation, and understanding their operational intricacies, you can help your clients harness the full potential of these machines, contributing to a more sustainable future.

Related Blog