Unlocking the Potential of Nylon Recycling Machines: A Guide for Professionals

Release Time:

Jul 19,2025

Nylon Recycling Machines have become increasingly important in today’s world as the demand for sustainable practices grows. This machinery plays a crucial role in converting waste nylon materials back into usable products, thus contributing to environmental conservation and resource efficiency. As a professional in the field of mechanical equipment maintenance, installation, and technical support,

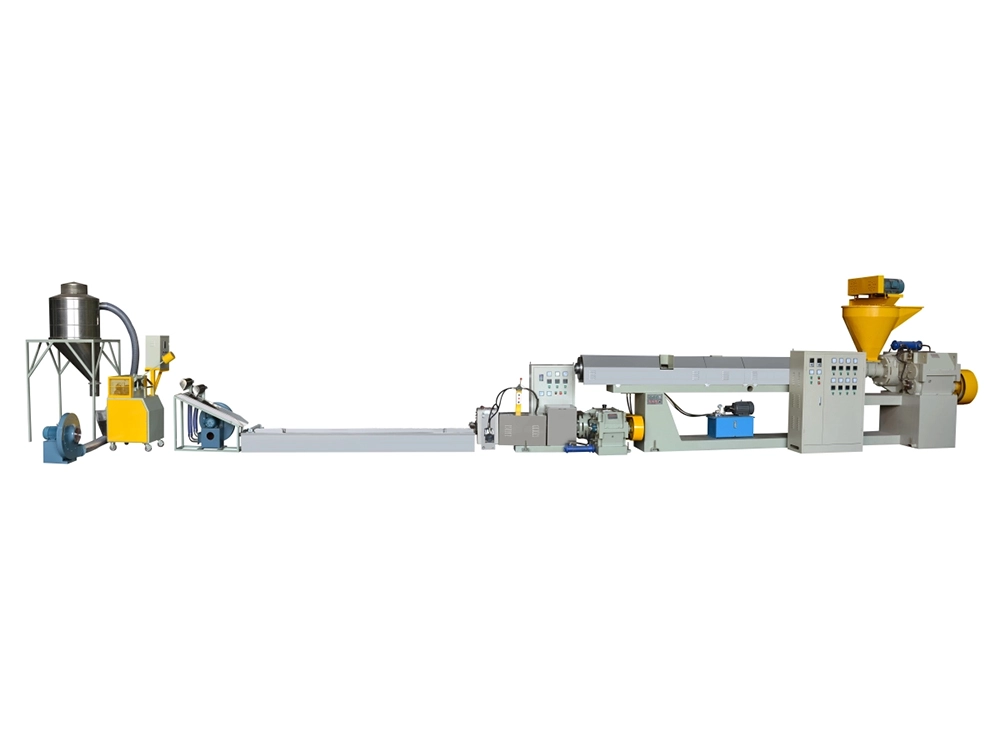

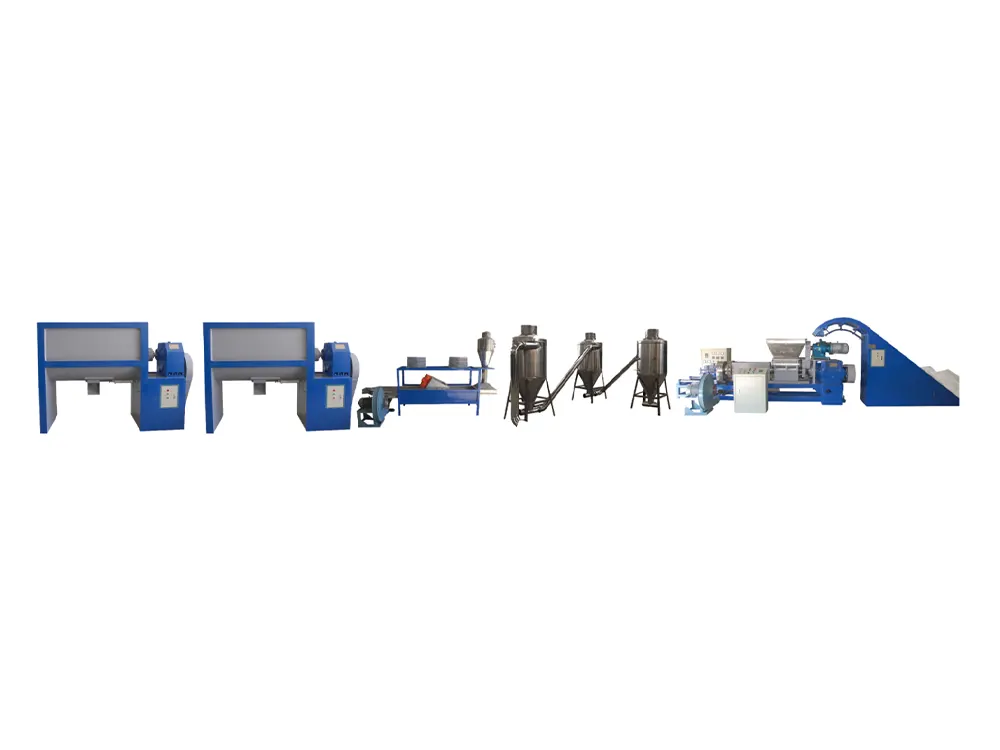

Nylon Recycling Machines have become increasingly important in today’s world as the demand for sustainable practices grows. This machinery plays a crucial role in converting waste nylon materials back into usable products, thus contributing to environmental conservation and resource efficiency. As a professional in the field of mechanical equipment maintenance, installation, and technical support, understanding the functionality and benefits of Nylon Recycling Machines can significantly enhance your service offerings.

Firstly, it’s essential to grasp how Nylon Recycling Machines operate. These machines typically utilize processes such as shredding, melting, and reforming to transform discarded nylon products into raw materials. Familiarity with these processes is vital for professionals responsible for their maintenance and repair. Regular servicing of these machines ensures optimal performance and longevity, which is paramount in maintaining efficiency in production lines.

Secondly, the market for recycled nylon is expanding due to increasing consumer awareness and regulatory requirements regarding sustainability. Companies are now more inclined to invest in recycling technologies. Therefore, understanding the operational benefits of Nylon Recycling Machines can provide a competitive edge. They not only help companies comply with environmental regulations but also reduce material costs by reintroducing recycled nylon into the production cycle.

Moreover, technical support for these machines is a critical aspect of service provision. Professionals in the field should be well-versed in troubleshooting common issues that may arise during operation. Issues can range from mechanical malfunctions to software glitches. A proactive maintenance schedule can mitigate these problems, ensuring that the machines run smoothly and efficiently, which is crucial for meeting production targets.

Training staff on the proper use and maintenance of Nylon Recycling Machines can also enhance overall efficiency. Knowledgeable technicians can quickly identify potential problems, leading to reduced downtime and increased productivity. This training can be integrated into your service offerings, providing added value to your clients.

In conclusion, as a professional in the mechanical service, installation, and technical support industry, understanding the intricacies of Nylon Recycling Machines is invaluable. By focusing on their functionality, market relevance, and the importance of regular maintenance, you can play a pivotal role in promoting sustainable practices while enhancing your technical service capabilities. Embracing this knowledge not only benefits your clients but also positions your business as a leader in eco-friendly solutions within the industry.

Firstly, it’s essential to grasp how Nylon Recycling Machines operate. These machines typically utilize processes such as shredding, melting, and reforming to transform discarded nylon products into raw materials. Familiarity with these processes is vital for professionals responsible for their maintenance and repair. Regular servicing of these machines ensures optimal performance and longevity, which is paramount in maintaining efficiency in production lines.

Secondly, the market for recycled nylon is expanding due to increasing consumer awareness and regulatory requirements regarding sustainability. Companies are now more inclined to invest in recycling technologies. Therefore, understanding the operational benefits of Nylon Recycling Machines can provide a competitive edge. They not only help companies comply with environmental regulations but also reduce material costs by reintroducing recycled nylon into the production cycle.

Moreover, technical support for these machines is a critical aspect of service provision. Professionals in the field should be well-versed in troubleshooting common issues that may arise during operation. Issues can range from mechanical malfunctions to software glitches. A proactive maintenance schedule can mitigate these problems, ensuring that the machines run smoothly and efficiently, which is crucial for meeting production targets.

Training staff on the proper use and maintenance of Nylon Recycling Machines can also enhance overall efficiency. Knowledgeable technicians can quickly identify potential problems, leading to reduced downtime and increased productivity. This training can be integrated into your service offerings, providing added value to your clients.

In conclusion, as a professional in the mechanical service, installation, and technical support industry, understanding the intricacies of Nylon Recycling Machines is invaluable. By focusing on their functionality, market relevance, and the importance of regular maintenance, you can play a pivotal role in promoting sustainable practices while enhancing your technical service capabilities. Embracing this knowledge not only benefits your clients but also positions your business as a leader in eco-friendly solutions within the industry.

Related Blog