Why Nylon Recycling Machines are Essential for Modern Businesses

Release Time:

Jul 14,2025

Why Nylon Recycling Machines are Essential for Modern Businesses Introduction to Nylon Recycling in Today's Economy In an era where sustainability is not just a buzzword but a necessity, **nylon recycling machines** stand out as a pivotal innovation for modern businesses. As industries grapple with the implications of plastic waste, adopting efficient recycling solutions has become crucial. Nylo

Why Nylon Recycling Machines are Essential for Modern Businesses

Introduction to Nylon Recycling in Today's Economy

In an era where sustainability is not just a buzzword but a necessity, **nylon recycling machines** stand out as a pivotal innovation for modern businesses. As industries grapple with the implications of plastic waste, adopting efficient recycling solutions has become crucial. Nylon, a versatile synthetic polymer, is commonly used in apparel, automotive parts, and various consumer goods. However, its environmental impact, when discarded improperly, poses significant challenges. Here, we explore why nylon recycling machines are not merely an option but an essential asset for businesses aiming to thrive in a sustainable economy.

The Growing Need for Nylon Recycling

Nylon’s durability and resilience make it a popular choice across multiple sectors. However, these very traits contribute to its environmental persistence, leading to several pressing issues:

The Environmental Impact of Nylon Waste

Every year, millions of tons of nylon waste end up in landfills, contributing to pollution and harming wildlife. Unlike natural fibers, nylon can take hundreds of years to decompose, leading to critical ecological consequences. By introducing **nylon recycling machines**, businesses can significantly reduce their carbon footprint and contribute to a circular economy.

Economic Incentives for Recycling Nylon

Investing in nylon recycling not only benefits the environment but also offers substantial economic advantages. Businesses that engage in recycling can reduce raw material costs, lower disposal fees, and even generate revenue from recycled materials. Moreover, as consumers increasingly favor sustainable brands, companies that prioritize recycling can enhance their market competitiveness.

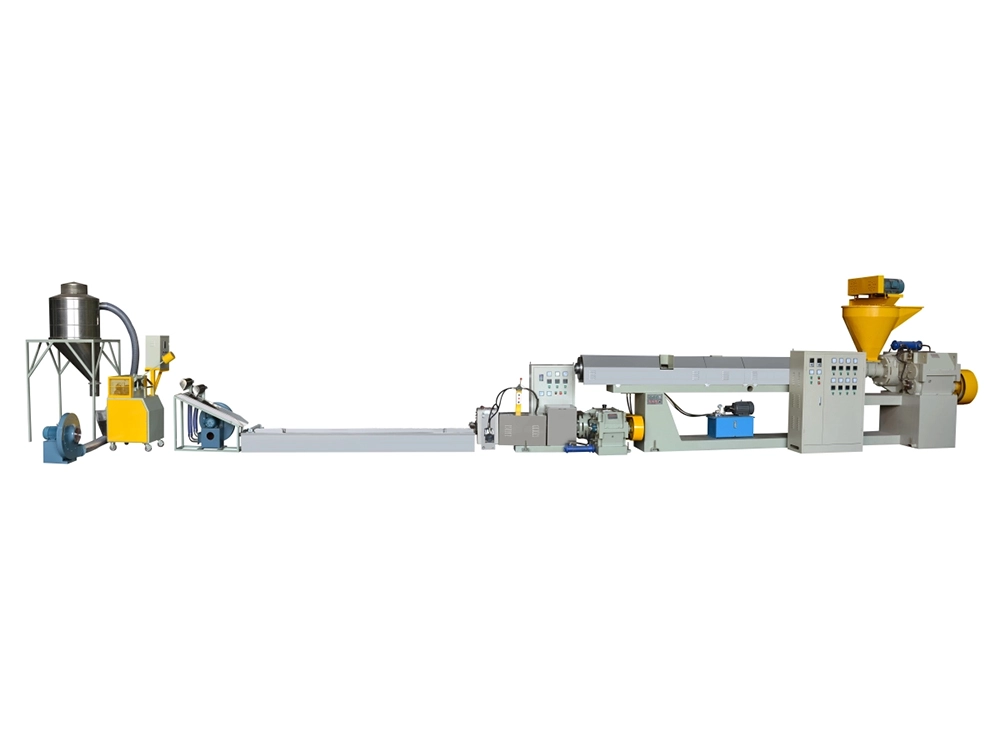

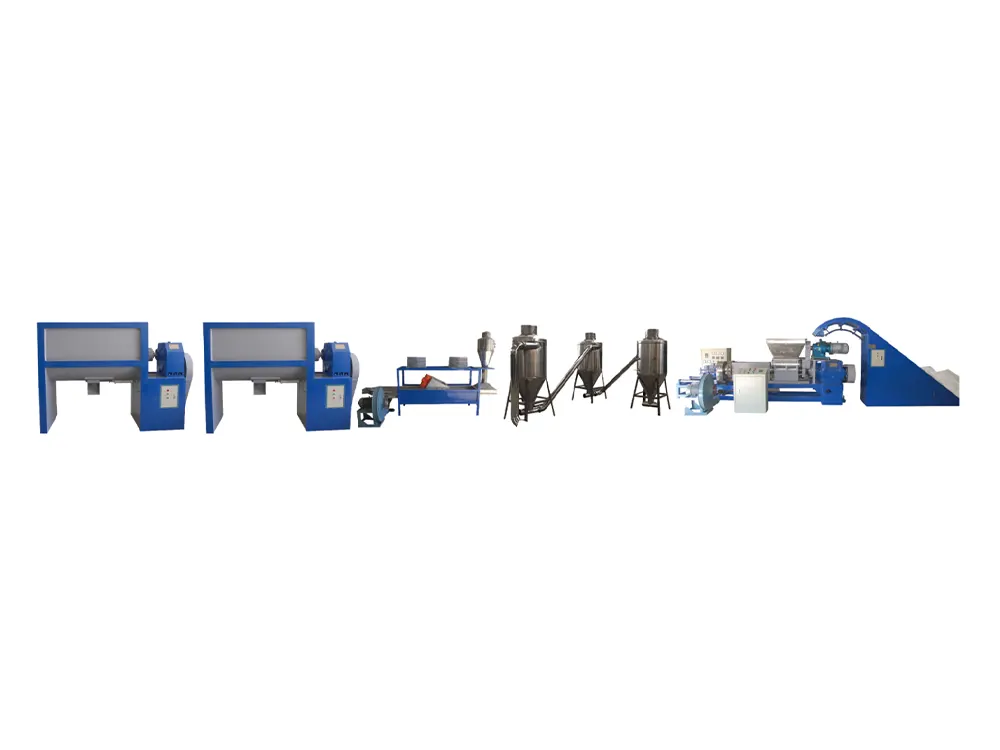

Understanding Nylon Recycling Machines

Nylon recycling machines are specialized equipment designed to process and repurpose discarded nylon products. They operate through various stages, ensuring that the nylon is efficiently reclaimed and transformed into reusable materials.

How Nylon Recycling Machines Work

The operation of nylon recycling machines involves several key steps:

Collection and Sorting

The initial phase involves collecting and sorting used nylon products. This step is crucial as it ensures that only suitable materials enter the recycling process, minimizing contamination.

Shredding and Grinding

Once sorted, the nylon waste is fed into shredders, where it is broken down into smaller pieces. This shredded nylon is then further ground into a fine powder, preparing it for the melting process.

Melting and Extrusion

The ground nylon undergoes heating, where it melts and can be extruded into new nylon products. The molten nylon is forced through a spinneret to form filaments, which can then be processed into various forms, such as fibers or sheets.

Quality Control and Repackaging

To ensure the integrity and quality of the recycled nylon, rigorous quality control measures are implemented. The final products are then repackaged and made available for resale or reintegration into manufacturing processes.

The Benefits of Nylon Recycling Machines for Businesses

Investing in nylon recycling machines offers numerous advantages that can significantly impact a business’s operations and reputation.

1. Cost Reduction and Resource Efficiency

By recycling nylon, businesses can tremendously reduce their reliance on virgin materials, leading to lower production costs. Additionally, recycling often incurs fewer expenses than waste disposal, translating to overall financial savings.

2. Enhanced Brand Reputation

Modern consumers are increasingly conscientious about their purchasing decisions. Companies that actively engage in eco-friendly practices, such as nylon recycling, can bolster their brand image and attract a growing segment of environmentally aware customers.

3. Compliance with Regulations

With governments worldwide implementing stricter regulations on plastic waste, companies that utilize nylon recycling machines can ensure compliance with environmental laws. This proactive approach not only mitigates legal risks but also positions businesses as responsible corporate citizens.

4. Innovation and Competitive Edge

Embracing nylon recycling technologies fosters innovation. Businesses that invest in recycling not only improve their processes but also create opportunities for new product development, allowing them to stay ahead in a competitive market.

5. Contribution to a Circular Economy

Nylon recycling machines play a vital role in promoting a circular economy, where products are reused and recycled rather than discarded. This shift not only conserves resources but also minimizes waste, contributing to a healthier planet for future generations.

Key Technologies in Nylon Recycling Machines

Understanding the technologies behind nylon recycling machines is essential for businesses looking to invest in these systems.

Advanced Sorting Technologies

Today’s nylon recycling machines incorporate advanced sorting technologies, such as AI and machine learning, to improve material identification and separation. This precision minimizes contamination and enhances the quality of recycled products.

Energy-Efficient Processing

Modern machines are designed to operate with energy efficiency in mind, significantly reducing energy costs associated with recycling. Innovations like regenerative heating systems contribute to lower energy consumption throughout the recycling process.

Integration with Automation

Automation is transforming the recycling landscape by streamlining operations and reducing labor costs. Automated nylon recycling machines can operate continuously, ensuring high throughput and efficiency.

Implementing Nylon Recycling in Your Business

For businesses looking to adopt nylon recycling, several key steps should be considered.

Assessing Your Current Waste Management Practices

Evaluate your current waste management practices to identify opportunities for integrating nylon recycling. Understanding the volume of nylon waste generated will help you determine the appropriate recycling solution.

Choosing the Right Nylon Recycling Machine

Select a nylon recycling machine that aligns with your business needs. Consider factors such as capacity, processing speed, and technology features to ensure optimal performance.

Training Your Team

Investing in training for your team is crucial. Understanding how to operate and maintain the recycling machinery will enhance efficiency and extend the lifespan of the equipment.

Developing Partnerships

Consider partnering with recycling experts or organizations that can provide additional support and resources. Collaborating with industry stakeholders can foster innovation and improve recycling outcomes.

Frequently Asked Questions (FAQs)

1. What types of nylon can be recycled?

Most types of nylon, including nylon 6 and nylon 66, can be recycled. However, it's essential to ensure that the material is clean and free from contaminants for effective recycling.

2. How can nylon recycling benefit my business financially?

Nylon recycling can reduce costs associated with raw materials and waste disposal, ultimately improving your bottom line. Additionally, recycled nylon can be sold, creating an additional revenue stream.

3. Are there any certifications for recycled nylon products?

Yes, there are certifications, such as Global Recycled Standard (GRS), that validate the content and quality of recycled materials. These certifications can enhance customer trust and marketability.

4. What is the typical lifespan of nylon recycling machines?

The lifespan of nylon recycling machines varies based on usage and maintenance but generally ranges from 10 to 15 years with proper care.

5. Can small businesses invest in nylon recycling technology?

Absolutely! There are various options for small businesses, including modular recycling machines that require less investment and space while still offering effective recycling solutions.

Conclusion

In summary, nylon recycling machines are not just a technological advancement but a necessity for modern businesses striving for sustainability and responsible resource management. By investing in these machines, companies can significantly reduce environmental impact, enhance brand reputation, and achieve economic benefits. As we continue to navigate the complexities of waste management and sustainability, adopting nylon recycling practices will not only benefit individual businesses but contribute to a greater global effort toward environmental stewardship. Embrace the change; the future of our planet depends on it.

Related Blog