The Essential Guide to Nylon Recycling Machine Suppliers: What You Need to Know

Release Time:

Jul 09,2025

Nylon is one of the most common synthetic materials, widely utilized in textiles, automotive parts, and various consumer goods. However, its durability, while advantageous for product longevity, poses significant challenges when it comes to waste management. This is where nylon recycling machine suppliers come into play, offering essential equipment that aids in the efficient processing of discard

Nylon is one of the most common synthetic materials, widely utilized in textiles, automotive parts, and various consumer goods. However, its durability, while advantageous for product longevity, poses significant challenges when it comes to waste management. This is where nylon recycling machine suppliers come into play, offering essential equipment that aids in the efficient processing of discarded nylon products.

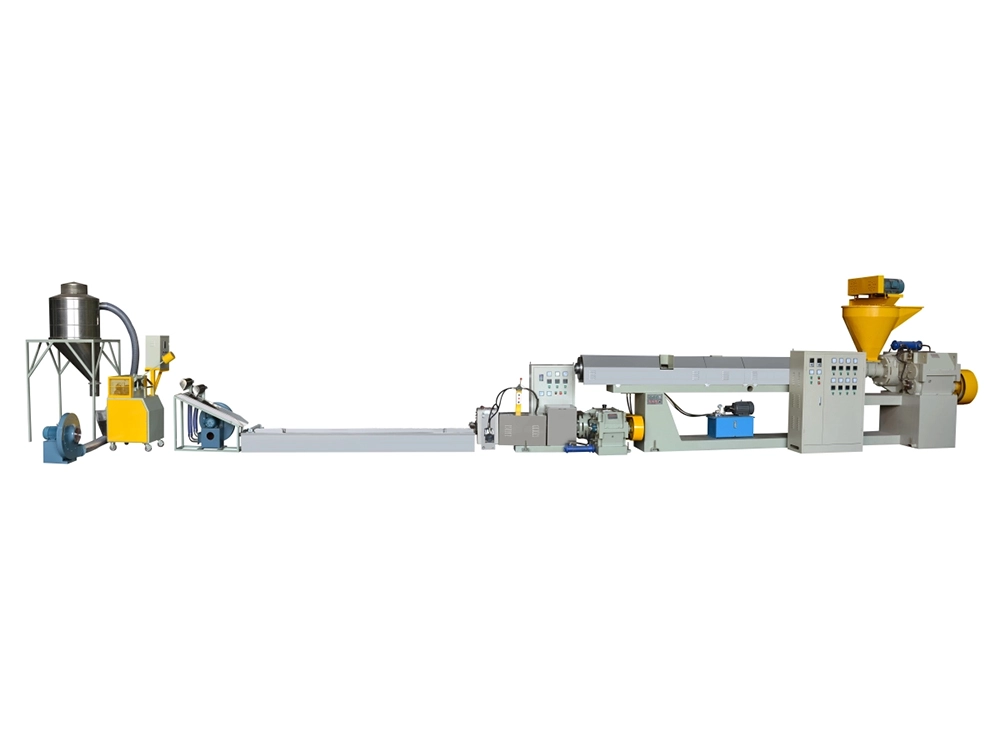

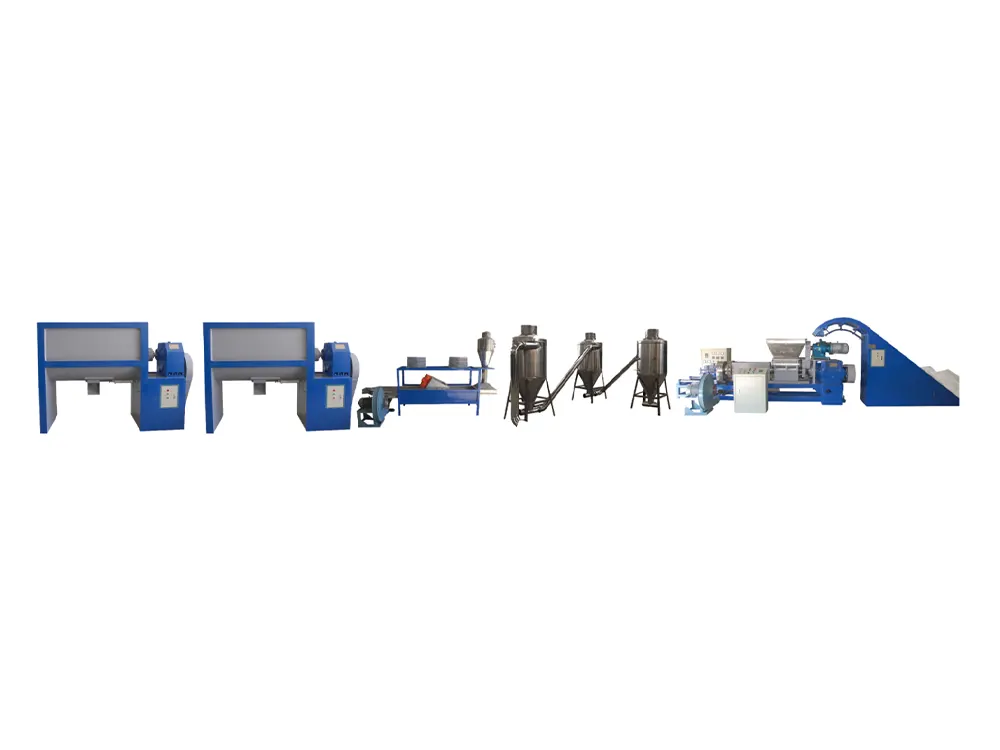

Recycling nylon not only helps reduce landfill waste but also conserves resources by enabling the reuse of materials in new products. The process typically involves shredding the nylon into smaller pieces, followed by melting and reforming it into pellets which can then be used to manufacture new items. Understanding this process can help businesses make informed decisions regarding the equipment they need.

When seeking nylon recycling machine suppliers, it’s crucial to consider a few key factors:

1. **Technology and Equipment Quality**: Advanced recycling machines that utilize cutting-edge technology can enhance efficiency and yield. Look for suppliers who offer machines that can handle diverse nylon types and are equipped with features that optimize energy consumption and minimize waste during the recycling process.

2. **Technical Support and Services**: Reliable suppliers should provide not only machines but also comprehensive technical support and maintenance services. This includes installation, training, and ongoing support to ensure that your recycling operations run smoothly. Given the complexity of machinery, having access to expert assistance can significantly reduce downtime and improve productivity.

3. **Reputation and Reliability**: Research potential suppliers to gauge their reputation in the industry. Customer reviews, case studies, and testimonials can provide insights into the performance of their equipment and the level of service they offer. Engaging with industry forums or networking with peers can also yield valuable recommendations.

4. **Adaptability and Customization**: Different businesses may have unique requirements based on the specific types of nylon they process. Select suppliers that offer customizable solutions that can be tailored to fit your operational needs, ensuring that the machines can evolve alongside your business.

5. **Sustainability Practices**: Given the growing importance of sustainability, consider suppliers that prioritize eco-friendly practices in their manufacturing and operations. This not only aligns with global sustainability goals but can also enhance your brand image by demonstrating your commitment to responsible recycling.

In conclusion, nylon recycling machine suppliers are pivotal in the shift towards more sustainable waste management practices. By understanding what to look for when selecting a supplier—from technology and support to reputation and sustainability—businesses can make informed choices that benefit both their operations and the environment. This knowledge is essential for professionals in the machinery service and repair industry, as it underscores the importance of effective recycling solutions in today’s eco-conscious market.

Recycling nylon not only helps reduce landfill waste but also conserves resources by enabling the reuse of materials in new products. The process typically involves shredding the nylon into smaller pieces, followed by melting and reforming it into pellets which can then be used to manufacture new items. Understanding this process can help businesses make informed decisions regarding the equipment they need.

When seeking nylon recycling machine suppliers, it’s crucial to consider a few key factors:

1. **Technology and Equipment Quality**: Advanced recycling machines that utilize cutting-edge technology can enhance efficiency and yield. Look for suppliers who offer machines that can handle diverse nylon types and are equipped with features that optimize energy consumption and minimize waste during the recycling process.

2. **Technical Support and Services**: Reliable suppliers should provide not only machines but also comprehensive technical support and maintenance services. This includes installation, training, and ongoing support to ensure that your recycling operations run smoothly. Given the complexity of machinery, having access to expert assistance can significantly reduce downtime and improve productivity.

3. **Reputation and Reliability**: Research potential suppliers to gauge their reputation in the industry. Customer reviews, case studies, and testimonials can provide insights into the performance of their equipment and the level of service they offer. Engaging with industry forums or networking with peers can also yield valuable recommendations.

4. **Adaptability and Customization**: Different businesses may have unique requirements based on the specific types of nylon they process. Select suppliers that offer customizable solutions that can be tailored to fit your operational needs, ensuring that the machines can evolve alongside your business.

5. **Sustainability Practices**: Given the growing importance of sustainability, consider suppliers that prioritize eco-friendly practices in their manufacturing and operations. This not only aligns with global sustainability goals but can also enhance your brand image by demonstrating your commitment to responsible recycling.

In conclusion, nylon recycling machine suppliers are pivotal in the shift towards more sustainable waste management practices. By understanding what to look for when selecting a supplier—from technology and support to reputation and sustainability—businesses can make informed choices that benefit both their operations and the environment. This knowledge is essential for professionals in the machinery service and repair industry, as it underscores the importance of effective recycling solutions in today’s eco-conscious market.

Related Blog