How to Choose the Right Nylon Recycling Machine for Your Needs

Release Time:

Jul 08,2025

How to Choose the Right Nylon Recycling Machine for Your Needs Nylon, a robust synthetic polymer, is widely used in various industries, from textiles to automotive applications. With increasing environmental concerns related to plastic waste, recycling nylon has become an essential practice. Selecting the right nylon recycling machine is crucial for businesses seeking to optimize their recycling p

How to Choose the Right Nylon Recycling Machine for Your Needs

Nylon, a robust synthetic polymer, is widely used in various industries, from textiles to automotive applications. With increasing environmental concerns related to plastic waste, recycling nylon has become an essential practice. Selecting the right nylon recycling machine is crucial for businesses seeking to optimize their recycling processes effectively. This article will guide you through the key considerations, types of machines available, and best practices for making an informed purchase decision.

Table of Contents

- Understanding Nylon Recycling

- The Importance of Recycling Nylon

- Types of Nylon Recycling Machines

- Key Features to Consider

- Capacity and Efficiency

- Cost Considerations

- Choosing the Right Manufacturer

- Maintenance and Support

- Conclusion

- FAQs

Understanding Nylon Recycling

The process of recycling nylon involves collecting, sorting, and reprocessing used nylon products to create new materials. This helps reduce landfill waste and lowers the demand for virgin nylon production. Understanding the recycling process is vital for choosing the right machine, as different machines cater to varying recycling methods and end product requirements.

The Importance of Recycling Nylon

Recycling nylon plays a crucial role in environmental sustainability. By recycling nylon, we can:

- Reduce Waste: Recycling keeps used nylon out of landfills, minimizing environmental pollution.

- Conserve Resources: Recycling nylon reduces the need for new raw materials, conserving energy and resources.

- Promote Circular Economy: Incorporating recycled nylon into production supports a circular economy, where materials are reused and repurposed.

Understanding these benefits can help businesses justify the investment in a nylon recycling machine.

Types of Nylon Recycling Machines

When considering a nylon recycling machine, various types are available, each designed for specific functions:

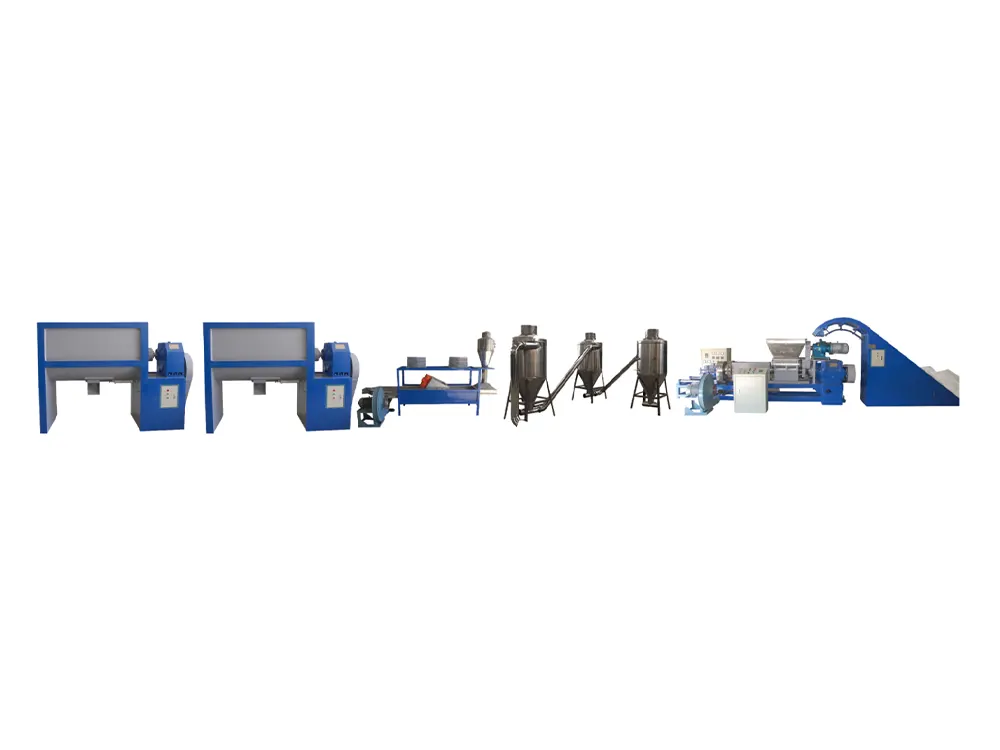

1. Shredders

Shredders are used to break down large nylon items into smaller pieces, facilitating easier handling and processing. They come in different sizes and capacities, making them suitable for varying scales of operations.

2. Granulators

Granulators process shredded nylon into granules, which can be easily melted and reused in manufacturing. They are essential for producing high-quality recycled nylon products.

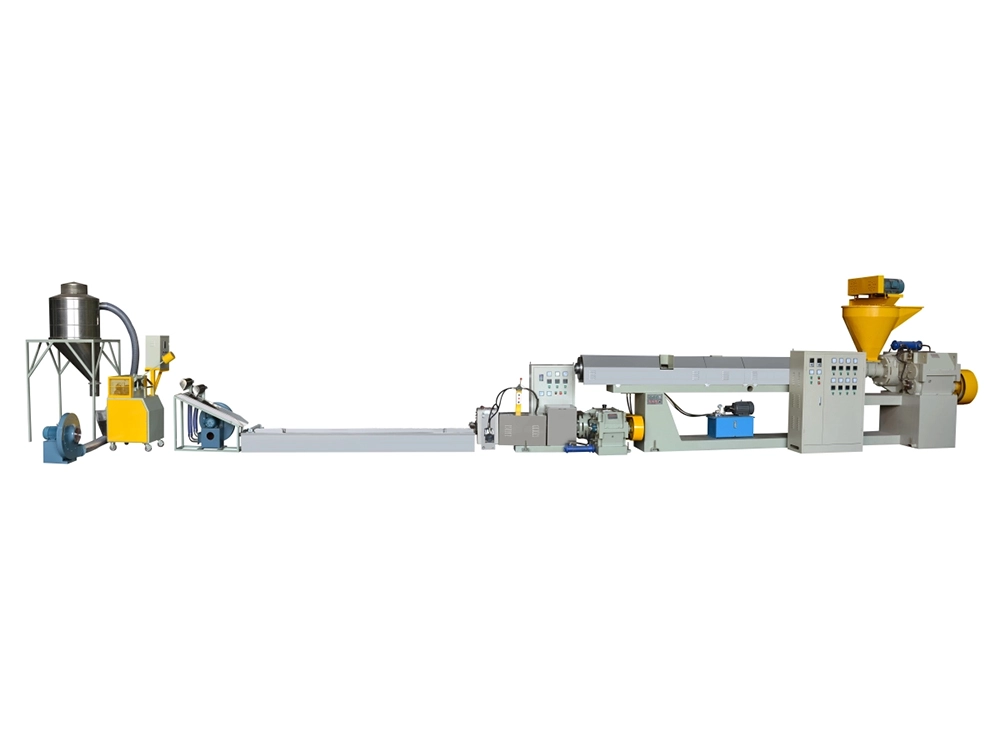

3. Extruders

Extruders convert nylon granules into usable nylon filament or fiber. These machines are vital for businesses looking to create new nylon products from recycled materials.

4. Washers

Washers are used to clean nylon materials before processing. They remove impurities and contaminants, ensuring the recycled output is of high quality.

Key Features to Consider

When choosing a nylon recycling machine, several key features should be evaluated:

1. Material Compatibility

Ensure the machine can process the specific type of nylon you intend to recycle, as different nylon forms (e.g., nylon 6, nylon 66) may require different handling techniques.

2. Energy Efficiency

Energy-efficient machines reduce operational costs and support environmentally friendly practices. Look for machines with energy-saving capabilities.

3. Automation and Control Systems

Advanced automation features can enhance efficiency and reduce labor costs. Look for machines with automated feeding, monitoring, and control systems for optimal performance.

4. Durability and Build Quality

A robust build ensures longevity and reduces maintenance costs. Check for machines made from high-quality materials that can withstand continuous operation.

Capacity and Efficiency

Determining the capacity and efficiency of a nylon recycling machine is critical for meeting production demands:

1. Production Volume

Assess your anticipated production volume to ensure the machine can handle your requirements. Different machines have varying capacities, so choose one that aligns with your operational goals.

2. Processing Speed

Efficiency in processing speed is vital for maintaining productivity. Evaluate the machine's throughput rate to ensure it meets your operational timeline.

Cost Considerations

The cost of a nylon recycling machine can vary significantly based on its features, capacity, and manufacturer. Consider the following:

1. Initial Investment

While a higher initial investment may seem daunting, consider the long-term savings from operational efficiency and energy savings.

2. Operating Costs

Evaluate ongoing operational expenses, including energy consumption, maintenance, and potential repairs. An efficient machine may have higher upfront costs but save money in the long run.

3. Return on Investment (ROI)

Calculate the potential ROI based on your production capacity, market demand for recycled nylon, and operational costs. This can help justify the investment in a nylon recycling machine.

Choosing the Right Manufacturer

Selecting the right manufacturer is crucial to ensure quality and support:

1. Reputation and Experience

Research potential manufacturers' reputations, focusing on their experience in the industry and customer reviews.

2. Support and Warranty

Choose a manufacturer that offers robust customer support and warranty options. This can safeguard your investment and ensure any issues are promptly addressed.

3. Customization Options

Some manufacturers offer customization options to meet specific needs. If you have unique requirements, seek manufacturers open to tailoring their products.

Maintenance and Support

Regular maintenance is essential for the longevity and efficiency of your nylon recycling machine:

1. Maintenance Requirements

Understand the maintenance needs of the machine. Ensure that you have the resources (both human and financial) to keep it in optimal condition.

2. Training and Support

Invest in training for your staff to operate and maintain the machine effectively. Manufacturers often provide training programs that can be beneficial.

Conclusion

Choosing the right nylon recycling machine is a critical decision that can significantly impact your recycling operations. By understanding the types of machines available, key features to consider, and working with reputable manufacturers, you can make an informed choice that meets your specific needs. Investing in the right machine not only supports environmental sustainability but also enhances your business's efficiency and profitability.

FAQs

1. What types of nylon can be recycled?

Nylon 6, nylon 66, and nylon blends can be recycled, but the recycling process may vary based on the type.

2. How do I know the right capacity for my recycling needs?

Evaluate your production volume requirements and future growth plans to determine the appropriate machine capacity.

3. Are there any grants or incentives for investing in recycling technology?

Many governments and organizations offer grants or incentives to businesses that invest in recycling technology to promote sustainability.

4. How can I ensure the machine is energy-efficient?

Look for machines with energy-saving features and certifications to ensure energy efficiency.

5. What is the average lifespan of a nylon recycling machine?

The lifespan varies based on usage and maintenance, but with proper care, a high-quality machine can last many years.

Related Blog