Understanding the Role of Nylon Recycling Machine Suppliers in Sustainable Manufacturing

Release Time:

Jul 07,2025

Nylon, a versatile synthetic polymer, is widely used in various applications, from textiles to automotive components. However, its durability, while advantageous, poses significant environmental challenges when it comes to waste disposal. As the world becomes increasingly aware of the need for sustainable practices, the role of nylon recycling machine suppliers has gained prominence. These supplie

Nylon, a versatile synthetic polymer, is widely used in various applications, from textiles to automotive components. However, its durability, while advantageous, poses significant environmental challenges when it comes to waste disposal. As the world becomes increasingly aware of the need for sustainable practices, the role of nylon recycling machine suppliers has gained prominence. These suppliers provide essential equipment that facilitates the recycling process, ensuring that nylon waste is effectively repurposed.

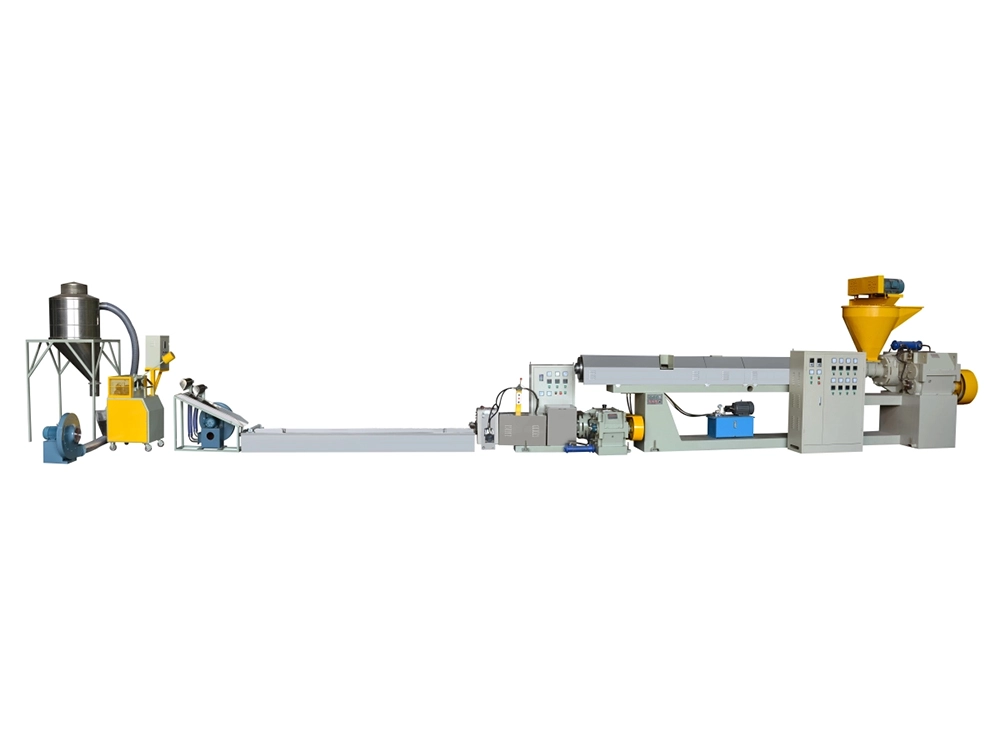

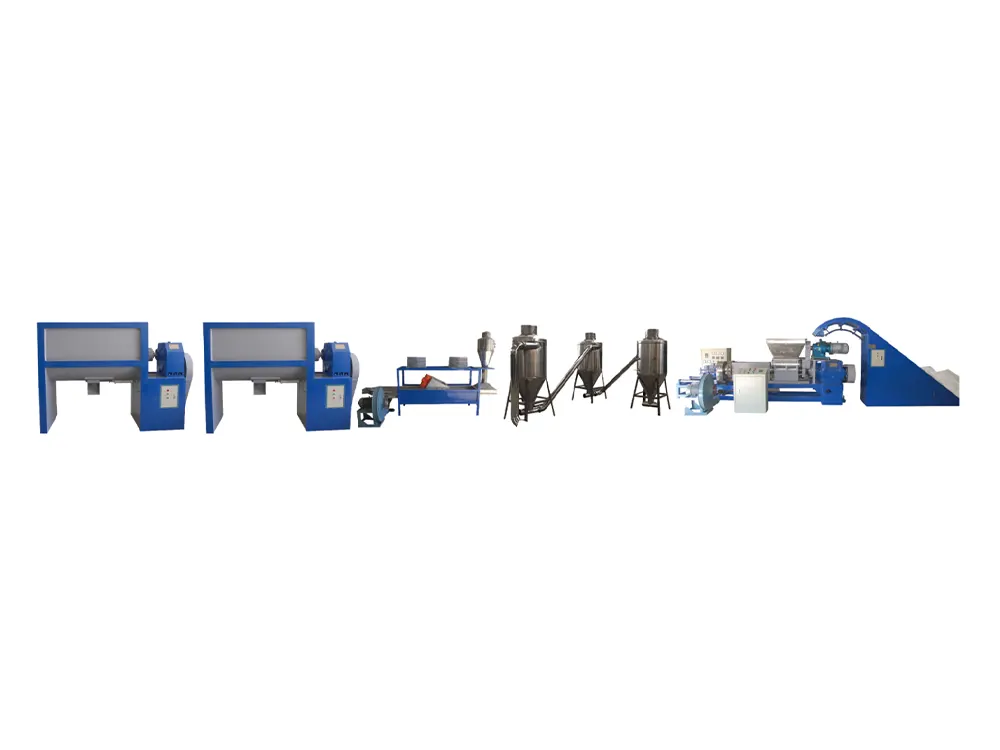

Nylon recycling machines operate by breaking down discarded nylon materials into reusable pellets or fibers. This process not only reduces the volume of waste sent to landfills but also conserves valuable resources by minimizing the need for virgin materials. The machines typically utilize advanced technologies such as mechanical grinding, washing, and melting, which contribute to efficient recycling. By investing in these machines, manufacturers can significantly reduce their environmental footprint while also appealing to eco-conscious consumers.

Additionally, nylon recycling machine suppliers often provide technical support and installation services, which are crucial for businesses looking to integrate recycling into their operations. Understanding how to operate and maintain these machines is vital for ensuring their longevity and efficiency. Suppliers usually offer training and ongoing technical assistance to help businesses navigate the complexities of recycling technology, fostering a smoother transition to sustainable practices.

Moreover, partnering with reliable nylon recycling machine suppliers can lead to innovation in product development. By working closely with suppliers, manufacturers can explore new possibilities for recycled nylon applications, leading to the creation of unique, eco-friendly products. This collaborative approach not only enhances the recycling process but also opens up new market opportunities.

In summary, the impact of nylon recycling machine suppliers extends far beyond merely providing equipment. They are integral to promoting sustainability within the manufacturing sector. By facilitating the recycling of nylon waste, they help conserve resources, reduce environmental pollution, and support businesses in adopting greener practices. As industries continue to seek more sustainable solutions, the importance of nylon recycling machine suppliers will undoubtedly grow, making them key players in the quest for a more sustainable future. Embracing their expertise and technology can lead to a significant positive change in how we manage nylon waste.

Nylon recycling machines operate by breaking down discarded nylon materials into reusable pellets or fibers. This process not only reduces the volume of waste sent to landfills but also conserves valuable resources by minimizing the need for virgin materials. The machines typically utilize advanced technologies such as mechanical grinding, washing, and melting, which contribute to efficient recycling. By investing in these machines, manufacturers can significantly reduce their environmental footprint while also appealing to eco-conscious consumers.

Additionally, nylon recycling machine suppliers often provide technical support and installation services, which are crucial for businesses looking to integrate recycling into their operations. Understanding how to operate and maintain these machines is vital for ensuring their longevity and efficiency. Suppliers usually offer training and ongoing technical assistance to help businesses navigate the complexities of recycling technology, fostering a smoother transition to sustainable practices.

Moreover, partnering with reliable nylon recycling machine suppliers can lead to innovation in product development. By working closely with suppliers, manufacturers can explore new possibilities for recycled nylon applications, leading to the creation of unique, eco-friendly products. This collaborative approach not only enhances the recycling process but also opens up new market opportunities.

In summary, the impact of nylon recycling machine suppliers extends far beyond merely providing equipment. They are integral to promoting sustainability within the manufacturing sector. By facilitating the recycling of nylon waste, they help conserve resources, reduce environmental pollution, and support businesses in adopting greener practices. As industries continue to seek more sustainable solutions, the importance of nylon recycling machine suppliers will undoubtedly grow, making them key players in the quest for a more sustainable future. Embracing their expertise and technology can lead to a significant positive change in how we manage nylon waste.

Related Blog