Maximize Efficiency with a Plastic Recycling Granulator Machine: The Ultimate Guide

Release Time:

Oct 02,2025

Maximize Efficiency with a Plastic Recycling Granulator Machine Table of Contents 1. Introduction to Plastic Recycling Granulator Machines 2. Understanding the Importance of Plastic Recycling 3. Key Features of a Plastic Recycling Granulator Machine 4. Types of Plastic Recycling Granulator Machines 5. How a Plastic Recycling Granulator Machine Works 6. Benefits of Using a Granulator

Maximize Efficiency with a Plastic Recycling Granulator Machine

Table of Contents

1. Introduction to Plastic Recycling Granulator Machines

2. Understanding the Importance of Plastic Recycling

3. Key Features of a Plastic Recycling Granulator Machine

4. Types of Plastic Recycling Granulator Machines

5. How a Plastic Recycling Granulator Machine Works

6. Benefits of Using a Granulator Machine in Plastic Recycling

7. Factors to Consider When Choosing a Granulator Machine

8. Maintenance and Technical Support for Granulator Machines

9. Frequently Asked Questions (FAQs)

10. Conclusion

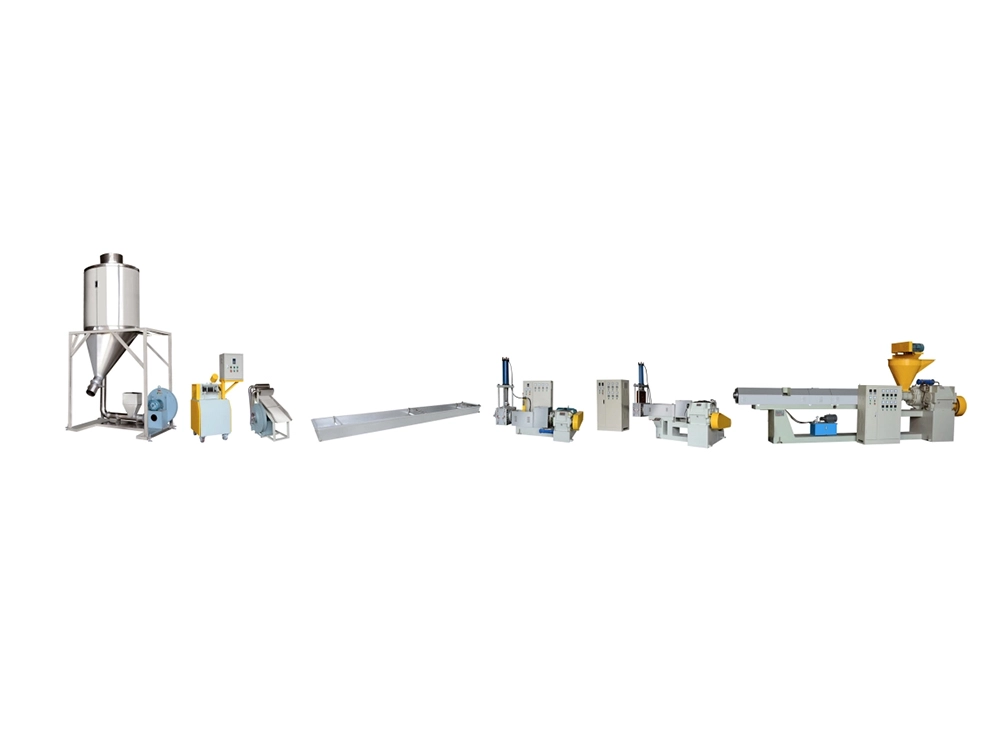

1. Introduction to Plastic Recycling Granulator Machines

Plastic recycling has become an essential aspect of modern waste management. As environmental concerns grow, industries are increasingly turning to methods that reduce plastic waste and encourage recycling. A **plastic recycling granulator machine** plays a pivotal role in this process by transforming plastic waste into reusable granules. This article delves into how these machines can maximize efficiency in recycling operations and contribute to a greener planet.

2. Understanding the Importance of Plastic Recycling

Plastic pollution poses a significant threat to ecosystems worldwide. With millions of tons of plastic waste generated annually, effective recycling methods are crucial. Plastic recycling helps reduce landfill waste, decreases the consumption of raw materials, and lowers greenhouse gas emissions. By investing in a plastic recycling granulator machine, businesses can enhance their recycling efforts and make a positive impact on the environment.

3. Key Features of a Plastic Recycling Granulator Machine

When selecting a plastic recycling granulator machine, it is essential to consider its features. Below are the key components that define a high-quality granulator:

3.1. Blades and Cutting Systems

The efficiency of a granulator largely depends on its blades. High-quality blades made from durable materials ensure effective cutting and shredding of plastic waste.

3.2. Motor Power

The motor's power determines the granulator's performance. A robust motor facilitates faster processing and higher output.

3.3. Feed Hopper Size

A large feed hopper allows for more plastic waste to be processed at once, increasing the machine's overall efficiency.

3.4. Control Systems

Modern granulators come equipped with advanced control systems that allow operators to monitor and adjust settings for optimal performance.

4. Types of Plastic Recycling Granulator Machines

Different types of plastic recycling granulators cater to various needs. Understanding these types can help businesses select the right machine for their specific requirements.

4.1. Single Shaft Granulators

These machines feature one rotating shaft and are ideal for processing large volumes of plastic waste.

4.2. Double Shaft Granulators

Double shaft granulators provide enhanced mixing and shredding capabilities, making them suitable for complex plastic materials.

4.3. Granulators with Screen Grates

These machines incorporate screen grates that allow for precise control over the size of the output granules.

5. How a Plastic Recycling Granulator Machine Works

The operation of a plastic recycling granulator machine involves several steps:

1. **Feeding**: Plastic waste is loaded into the feed hopper.

2. **Shredding**: The blades rotate and shred the plastic into smaller pieces.

3. **Granulation**: The shredded plastic is further processed to create uniform granules.

4. **Collection**: The granulated material is collected for reuse or further processing.

This streamlined process ensures efficiency and maximizes output, making it a crucial investment for recycling operations.

6. Benefits of Using a Granulator Machine in Plastic Recycling

Investing in a plastic recycling granulator machine offers numerous advantages:

6.1. Cost-Effectiveness

Granulators reduce waste disposal costs by converting plastic waste into valuable raw materials, lowering the need for purchasing virgin plastics.

6.2. Consistency in Output

The granulation process produces uniform granules, ensuring high quality in the recycled material.

6.3. Environmental Impact

The efficient processing of plastic waste minimizes landfill contributions and promotes sustainability.

6.4. Increased Productivity

With advanced features and high processing speeds, granulators enhance productivity, allowing businesses to process more plastic in less time.

7. Factors to Consider When Choosing a Granulator Machine

Selecting the right plastic recycling granulator machine requires careful consideration of several factors:

7.1. Type of Plastic Materials

Different machines are designed to handle various types of plastics. Understanding the materials you aim to recycle is crucial.

7.2. Processing Capacity

Evaluate your operational needs to determine the required processing capacity of the granulator.

7.3. Maintenance Requirements

Select a machine that aligns with your maintenance capabilities, ensuring longevity and optimal performance.

7.4. Budget and ROI

Consider the initial investment against the long-term savings and potential returns from increased recycling efficiency.

8. Maintenance and Technical Support for Granulator Machines

Regular maintenance is essential for the longevity and effective performance of plastic recycling granulator machines.

8.1. Routine Maintenance Practices

Implement a routine maintenance schedule that includes blade sharpening, motor checks, and cleaning to prevent downtime.

8.2. Technical Support Services

Choose a manufacturer that offers reliable technical support and service options to address any issues quickly.

8.3. Training for Operators

Providing training for operators ensures they understand the machine's features and maintenance requirements, enhancing safety and efficiency.

9. Frequently Asked Questions (FAQs)

9.1. What types of plastic can be processed with a granulator machine?

Granulator machines can process various plastics, including PET, HDPE, LDPE, and PP, among others.

9.2. How often should I perform maintenance on my granulator machine?

Regular maintenance should be conducted based on usage, but a general guideline is at least once every month.

9.3. Can I recycle contaminated plastic using a granulator machine?

Contaminated plastics may require pre-cleaning or specialized processing before granulation.

9.4. What is the typical lifespan of a plastic recycling granulator machine?

With proper maintenance, a granulator can last anywhere from 10 to 20 years, depending on usage and quality.

9.5. Are there any safety precautions to consider when operating a granulator machine?

Yes, operators should follow safety guidelines, including wearing protective gear and ensuring proper training on machine operation.

10. Conclusion

In the ever-evolving landscape of plastic recycling, investing in a plastic recycling granulator machine is a strategic decision that can significantly maximize efficiency and productivity. By understanding the features, advantages, and best practices associated with these machines, businesses can not only enhance their operational capabilities but also contribute positively to environmental sustainability. Embracing this technology is not just an investment in equipment; it is a commitment to a cleaner, greener future. Whether you are a small business or a large-scale operation, the right granulator can transform your plastic waste into valuable resources, demonstrating that effective recycling is within reach for everyone.

Related Blog