Understanding Plastic Crusher Machines: Essential Insights for Professionals

Release Time:

Sep 27,2025

Plastic crusher machines play a vital role in the recycling industry, offering an effective solution for managing plastic waste. These machines are designed to shred plastic materials into smaller pieces, making them easier to process and recycle. Understanding the operational mechanics of plastic crushers is essential for professionals engaged in machinery maintenance and installation. At the cor

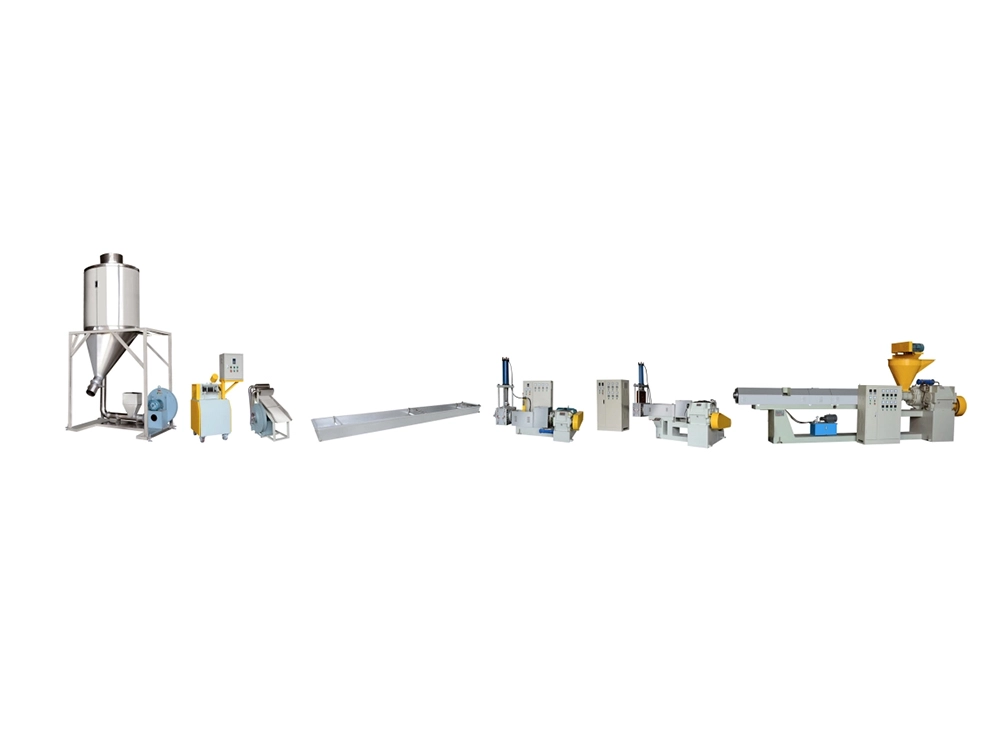

Plastic crusher machines play a vital role in the recycling industry, offering an effective solution for managing plastic waste. These machines are designed to shred plastic materials into smaller pieces, making them easier to process and recycle. Understanding the operational mechanics of plastic crushers is essential for professionals engaged in machinery maintenance and installation.

At the core of a plastic crusher machine is its cutting mechanism, which typically consists of sharp blades that can handle various types of plastics, including polyethylene, polypropylene, and other thermoplastics. The machine operates by feeding plastic waste into the hopper, where it is then transported to the cutting chamber. The blades rotate rapidly, shredding the plastic into granules that can be further processed or recycled.

One of the primary benefits of using a plastic crusher machine is its ability to significantly reduce the volume of plastic waste, facilitating easier transportation and storage. This reduction in size not only promotes efficient recycling efforts but also contributes to environmental sustainability by minimizing landfill usage. Furthermore, the granulated plastic can be reused in manufacturing new products, thereby conserving resources and reducing the overall carbon footprint.

When it comes to maintenance, regular checks and servicing are crucial to ensure the machine operates smoothly. Professionals should pay close attention to the sharpness of the blades, as dull blades can lead to inefficient shredding and increased energy consumption. Additionally, lubrication of moving parts is essential to prevent wear and tear and to prolong the lifespan of the machine.

Technical support is another critical aspect of operating plastic crusher machines. Professionals must be well-versed in troubleshooting common issues that may arise, such as jamming or motor malfunctions. A well-trained technician can quickly diagnose problems and implement effective solutions, reducing downtime and maintaining productivity in recycling operations.

In summary, plastic crusher machines are indispensable in the effort to manage plastic waste effectively. By understanding their functionality, benefits, and maintenance requirements, professionals in the field can enhance their operational efficiency and contribute to a more sustainable environment. Whether you are involved in machinery repair, installation, or providing technical support, gaining insights into these machines will be invaluable in your line of work.

At the core of a plastic crusher machine is its cutting mechanism, which typically consists of sharp blades that can handle various types of plastics, including polyethylene, polypropylene, and other thermoplastics. The machine operates by feeding plastic waste into the hopper, where it is then transported to the cutting chamber. The blades rotate rapidly, shredding the plastic into granules that can be further processed or recycled.

One of the primary benefits of using a plastic crusher machine is its ability to significantly reduce the volume of plastic waste, facilitating easier transportation and storage. This reduction in size not only promotes efficient recycling efforts but also contributes to environmental sustainability by minimizing landfill usage. Furthermore, the granulated plastic can be reused in manufacturing new products, thereby conserving resources and reducing the overall carbon footprint.

When it comes to maintenance, regular checks and servicing are crucial to ensure the machine operates smoothly. Professionals should pay close attention to the sharpness of the blades, as dull blades can lead to inefficient shredding and increased energy consumption. Additionally, lubrication of moving parts is essential to prevent wear and tear and to prolong the lifespan of the machine.

Technical support is another critical aspect of operating plastic crusher machines. Professionals must be well-versed in troubleshooting common issues that may arise, such as jamming or motor malfunctions. A well-trained technician can quickly diagnose problems and implement effective solutions, reducing downtime and maintaining productivity in recycling operations.

In summary, plastic crusher machines are indispensable in the effort to manage plastic waste effectively. By understanding their functionality, benefits, and maintenance requirements, professionals in the field can enhance their operational efficiency and contribute to a more sustainable environment. Whether you are involved in machinery repair, installation, or providing technical support, gaining insights into these machines will be invaluable in your line of work.

Related Blog