The Essential Guide to Plastic Crusher Machines: Understanding Their Role in Recycling

Release Time:

Sep 17,2025

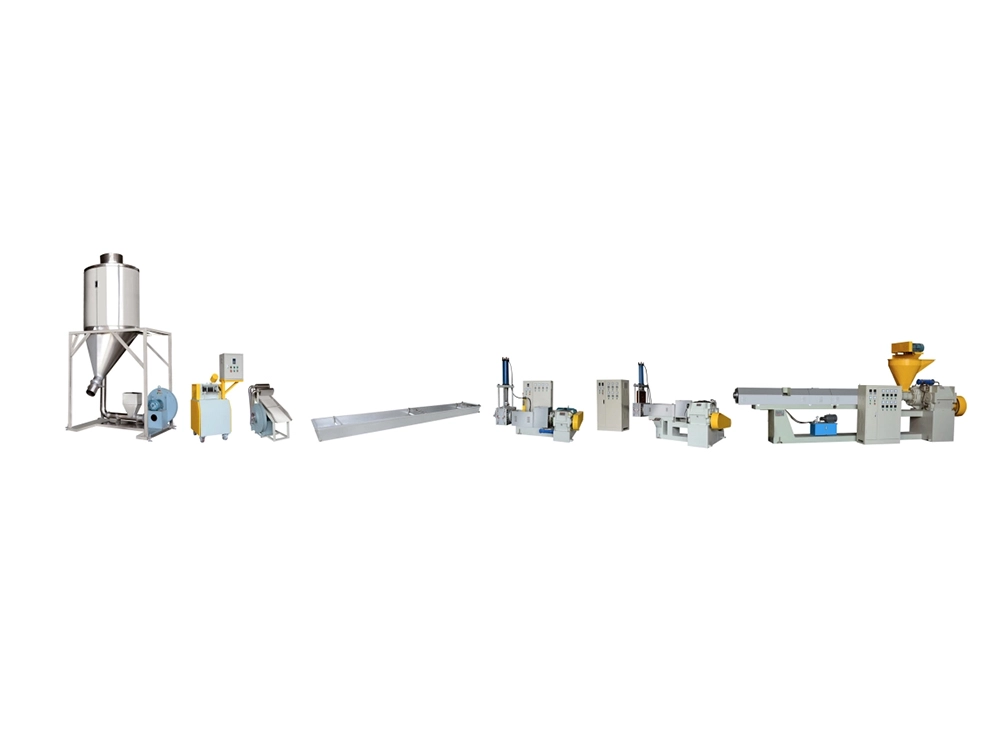

Plastic crusher machines are vital tools in the recycling process, particularly for managing plastic waste. As the world grapples with increasing plastic pollution, understanding the importance and functionality of these machines becomes crucial for both businesses and individuals involved in waste management and recycling efforts. A plastic crusher machine is designed to break down large pieces o

Plastic crusher machines are vital tools in the recycling process, particularly for managing plastic waste. As the world grapples with increasing plastic pollution, understanding the importance and functionality of these machines becomes crucial for both businesses and individuals involved in waste management and recycling efforts.

A plastic crusher machine is designed to break down large pieces of plastic into smaller, manageable pieces, known as plastic flakes or granules. This process is essential for recycling because it allows the plastic to be processed more efficiently in subsequent manufacturing stages. By reducing the size of plastic waste, these machines facilitate easier handling, transportation, and reprocessing of materials.

One of the primary advantages of using a plastic crusher machine is its ability to significantly minimize waste volume. By shredding and grinding various types of plastic, the machine enables recycling centers to handle larger quantities of material without compromising on efficiency. Additionally, the mechanical process of crushing helps improve the quality of the recycled material, making it more suitable for reuse in manufacturing new plastic products.

When selecting a plastic crusher machine, it's crucial to consider factors such as the type of plastic being processed, the desired output size, and the machine's capacity. There are different models available, each designed for specific applications, making it essential to choose one that aligns with your recycling goals.

Maintaining a plastic crusher machine is critical for ensuring its longevity and performance. Regular inspection and upkeep are necessary to prevent wear and tear, which can lead to costly repairs or downtime. It's advisable to follow the manufacturer's guidelines for maintenance schedules and to replace worn parts promptly to keep the machine running smoothly.

In the context of servicing and installation, understanding the operational aspects of plastic crusher machines can greatly enhance technical support and maintenance services. Being knowledgeable about the common issues that may arise, such as jamming or motor failures, can aid technicians in providing efficient solutions to clients.

As the demand for sustainable practices continues to rise, investing in a plastic crusher machine represents a proactive step towards reducing environmental impact. By effectively managing plastic waste, businesses can contribute to a circular economy, where materials are reused and recycled, thus minimizing the reliance on new plastic production.

In conclusion, plastic crusher machines play a pivotal role in the recycling landscape. Their ability to process plastic waste efficiently not only aids in waste reduction but also promotes a more sustainable future. By understanding their functionality and maintenance needs, businesses and individuals alike can maximize their impact in the fight against plastic pollution.

A plastic crusher machine is designed to break down large pieces of plastic into smaller, manageable pieces, known as plastic flakes or granules. This process is essential for recycling because it allows the plastic to be processed more efficiently in subsequent manufacturing stages. By reducing the size of plastic waste, these machines facilitate easier handling, transportation, and reprocessing of materials.

One of the primary advantages of using a plastic crusher machine is its ability to significantly minimize waste volume. By shredding and grinding various types of plastic, the machine enables recycling centers to handle larger quantities of material without compromising on efficiency. Additionally, the mechanical process of crushing helps improve the quality of the recycled material, making it more suitable for reuse in manufacturing new plastic products.

When selecting a plastic crusher machine, it's crucial to consider factors such as the type of plastic being processed, the desired output size, and the machine's capacity. There are different models available, each designed for specific applications, making it essential to choose one that aligns with your recycling goals.

Maintaining a plastic crusher machine is critical for ensuring its longevity and performance. Regular inspection and upkeep are necessary to prevent wear and tear, which can lead to costly repairs or downtime. It's advisable to follow the manufacturer's guidelines for maintenance schedules and to replace worn parts promptly to keep the machine running smoothly.

In the context of servicing and installation, understanding the operational aspects of plastic crusher machines can greatly enhance technical support and maintenance services. Being knowledgeable about the common issues that may arise, such as jamming or motor failures, can aid technicians in providing efficient solutions to clients.

As the demand for sustainable practices continues to rise, investing in a plastic crusher machine represents a proactive step towards reducing environmental impact. By effectively managing plastic waste, businesses can contribute to a circular economy, where materials are reused and recycled, thus minimizing the reliance on new plastic production.

In conclusion, plastic crusher machines play a pivotal role in the recycling landscape. Their ability to process plastic waste efficiently not only aids in waste reduction but also promotes a more sustainable future. By understanding their functionality and maintenance needs, businesses and individuals alike can maximize their impact in the fight against plastic pollution.

Related Blog