Maximize Efficiency: The Role of Plastic Crusher Machines in Recycling

Release Time:

Sep 12,2025

Maximize Efficiency: The Role of Plastic Crusher Machines in Recycling Introduction to Plastic Crusher Machines In today's environmentally conscious world, the importance of recycling cannot be overstated. Plastic waste has become a significant concern, leading to the need for efficient waste management solutions. **Plastic crusher machines** play a pivotal role in this process by facilitating

Maximize Efficiency: The Role of Plastic Crusher Machines in Recycling

Introduction to Plastic Crusher Machines

In today's environmentally conscious world, the importance of recycling cannot be overstated. Plastic waste has become a significant concern, leading to the need for efficient waste management solutions. **Plastic crusher machines** play a pivotal role in this process by facilitating the recycling of plastic materials. These machines are designed to reduce the size of plastic waste, making it easier to process and recycle. In this article, we will explore the various functions, benefits, and innovations surrounding plastic crusher machines and their critical role in maximizing recycling efficiency.

The Importance of Recycling Plastic Waste

Plastic pollution has become a pressing issue, impacting ecosystems, wildlife, and human health. Recycling plastic helps mitigate these effects by reducing the amount of waste sent to landfills and decreasing the demand for new plastic production. By reprocessing plastic materials, we can conserve natural resources, save energy, and reduce greenhouse gas emissions.

The Role of Plastic Crusher Machines in Recycling

Plastic crusher machines are essential in the recycling process. They break down larger plastic items into smaller, manageable pieces, making it easier for subsequent processing stages. This process enhances the efficiency of recycling operations and ensures that materials can be effectively reused.

How Plastic Crusher Machines Work

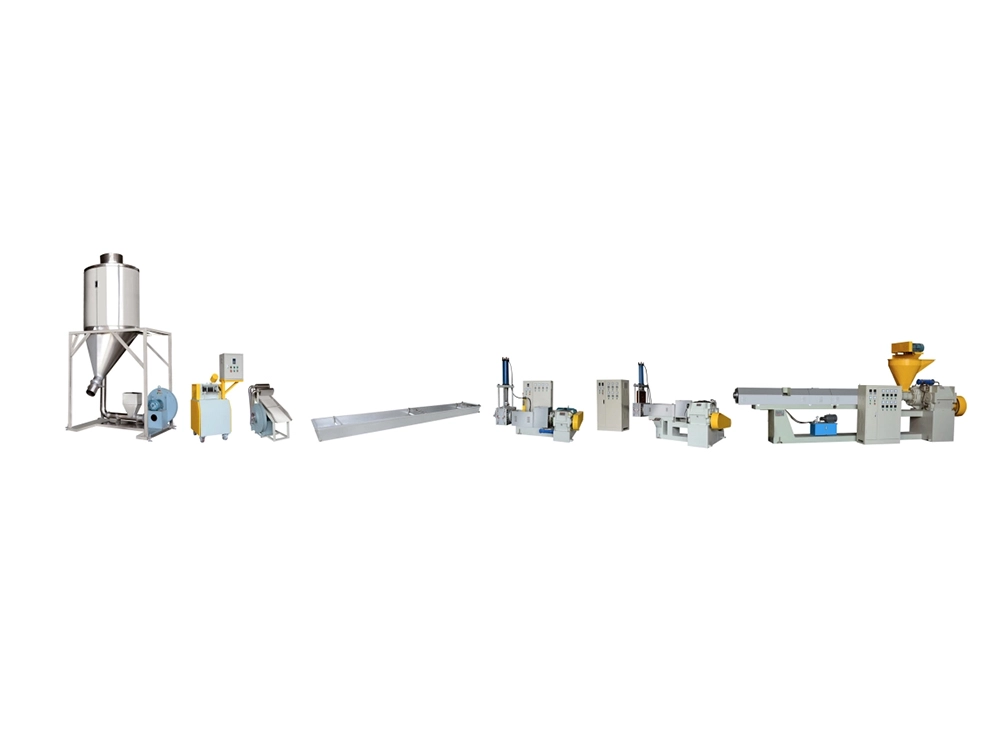

The operational mechanics of plastic crusher machines involve several key components. Typically, these machines consist of a feed hopper, a crushing chamber, and a collection system. The process begins when plastic waste is fed into the hopper, where it is guided into the crushing chamber. Here, powerful blades rotate and shred the material into smaller pieces. Once crushed, the plastic is collected for further processing, such as washing, drying, and granulating.

Types of Plastic Crushers

Several types of plastic crusher machines are available, each tailored to specific recycling needs. Understanding the differences can help businesses choose the right equipment for their operations.

1. Granulators

Granulators are designed for high-volume processing of plastic waste. They use rotary blades to grind plastic into granules, making them suitable for recycling purposes. These machines are commonly used in manufacturing facilities to recycle plastic offcuts and defective products.

2. Shredders

Shredders are another type, focusing on reducing plastic waste into smaller pieces rather than granules. They are versatile and can handle a variety of plastic types, making them ideal for mixed plastic waste streams.

3. Crushers

Crushers primarily focus on breaking down large plastic items into smaller fragments. They are often used in the initial stages of the recycling process to prepare materials for further processing.

Benefits of Using Plastic Crusher Machines

Investing in plastic crusher machines offers numerous advantages, particularly for businesses involved in recycling and waste management.

1. Increased Efficiency

By streamlining the initial stages of recycling, plastic crushers enhance overall efficiency. Smaller plastic particles require less energy to process, thus speeding up the recycling cycle.

2. Cost Savings

Reducing waste and improving recycling processes can lead to significant cost savings. Efficient plastic processing minimizes operational expenses and maximizes return on investment.

3. Environmental Impact

Using plastic crusher machines significantly reduces the carbon footprint associated with plastic recycling. By facilitating the quick recycling of plastic waste, these machines help conserve natural resources and decrease pollution.

Innovative Technologies in Plastic Crushing

The recycling industry is continuously evolving, and advances in technology play a significant role in enhancing the efficiency and effectiveness of plastic crusher machines.

1. Smart Technology Integration

Modern plastic crushers are increasingly equipped with smart technology, allowing for real-time monitoring and optimization of machine performance. This enhances operational efficiency and minimizes downtime.

2. Energy-Efficient Designs

Newer models of plastic crusher machines are designed to consume less energy, making them more environmentally friendly. These machines are engineered to maximize power usage while minimizing waste.

3. Enhanced Safety Features

Safety is paramount in any industrial operation. Advances in technology have led to the development of safer plastic crushers, incorporating features that minimize risks for operators.

Best Practices for Operating Plastic Crusher Machines

To maximize the effectiveness of plastic crusher machines, it is essential to follow best practices in operation and maintenance.

1. Regular Maintenance

Routine maintenance checks can prevent mechanical failures and prolong the lifespan of plastic crushers. Implementing a schedule for blade sharpening and system inspections is crucial for optimal performance.

2. Proper Material Sorting

Effective sorting of plastic waste before it reaches the crusher can enhance operational efficiency. Separate different types of plastics to ensure the machine operates smoothly and reduces the risk of jams.

3. Operator Training

Investing in comprehensive training for operators can significantly impact the efficiency of plastic crushers. Well-trained personnel are more adept at identifying issues and maintaining machines.

Challenges in Plastic Recycling and How Crushers Can Help

Despite the advancements in recycling technology, challenges still exist in the plastic recycling process. However, plastic crusher machines can help address some of these issues.

1. Contamination of Plastic Waste

Contaminants such as food residues or non-plastic materials can hinder recycling efforts. Proper crushing and sorting techniques can help separate contaminants during the initial stages of processing.

2. Mixed Plastic Streams

Many recycling facilities deal with mixed plastic waste, which complicates the recycling process. Plastic crushers can efficiently break down these mixed streams, allowing for better sorting and processing downstream.

3. Economic Viability

The fluctuating prices of recycled materials can pose a challenge. By improving efficiency and reducing processing costs, plastic crushers can enhance the economic viability of recycling operations.

Future of Plastic Recycling Technology

As technology continues to evolve, the future of plastic recycling looks promising. Ongoing research and development initiatives are focusing on creating more efficient and effective plastic processing solutions.

1. Advanced Material Science

Innovations in material science aim to develop new types of plastics that are easier to recycle. This will significantly impact the efficiency of plastic crushers and the overall recycling process.

2. Automation and AI Integration

The integration of automation and artificial intelligence in recycling facilities can streamline operations, improve sorting accuracy, and enhance machine performance, including plastic crushers.

3. Global Collaboration Efforts

International partnerships and collaborations are essential in addressing the global plastic crisis. Sharing knowledge, technology, and best practices can lead to innovative solutions in plastic recycling.

Conclusion

In conclusion, plastic crusher machines are integral to maximizing efficiency in the recycling of plastic waste. They play a crucial role in breaking down plastic materials, ultimately enhancing recycling processes and contributing to sustainability efforts. By adopting advanced technologies and following best practices, businesses can improve operational efficiency, reduce costs, and minimize environmental impact. As we continue to face the challenges of plastic pollution, the role of plastic crushers will only become more vital in shaping a sustainable future.

Related Blog