Understanding Granulator Machines: Essential Insights for Professionals

Release Time:

Sep 07,2025

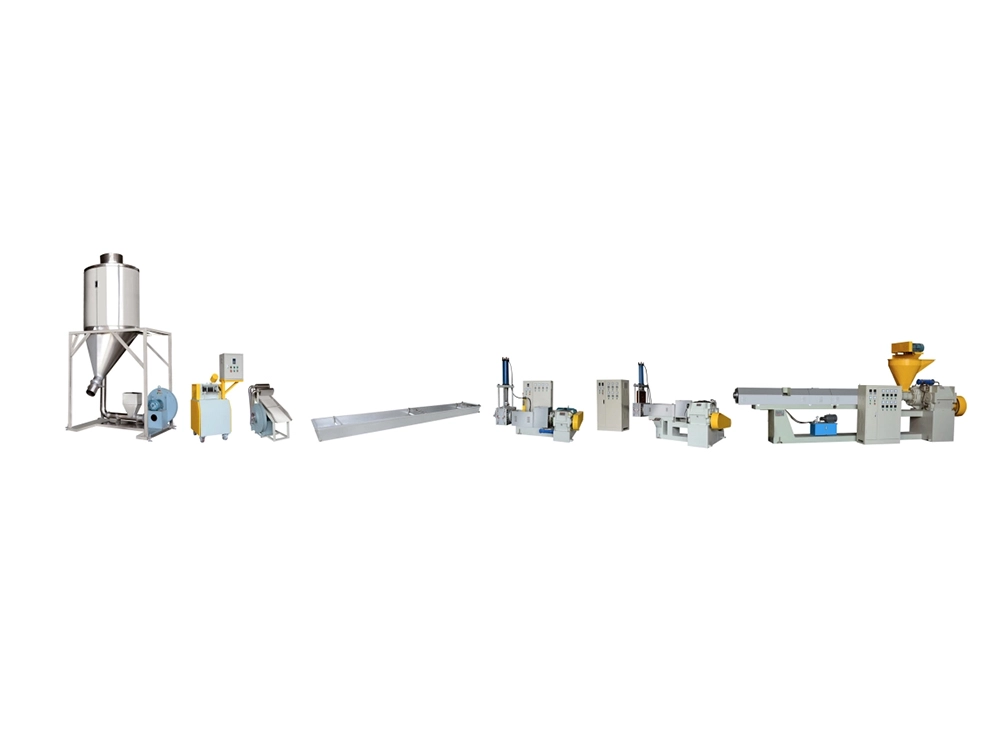

Granulator machines play a pivotal role in various industries by transforming raw materials into manageable sizes for further processing. These machines are designed to crush, shred, or granulate materials, making them essential in the production of plastics, pharmaceuticals, chemicals, and food products. Understanding the workings of granulator machines is crucial for professionals involved in ma

Granulator machines play a pivotal role in various industries by transforming raw materials into manageable sizes for further processing. These machines are designed to crush, shred, or granulate materials, making them essential in the production of plastics, pharmaceuticals, chemicals, and food products. Understanding the workings of granulator machines is crucial for professionals involved in maintenance, installation, and technical support of mechanical equipment.

At its core, a granulator operates by utilizing rotating blades to cut materials into smaller, more uniform pieces. The process begins when the raw material is fed into the machine, where the blades chop it down to the desired granule size. This process not only enhances the material's surface area but also facilitates easier handling and processing in downstream applications. Granulator machines are often equipped with adjustable screens that allow operators to control the particle size, making them versatile in their applications.

Regular maintenance is key to ensuring that granulator machines function efficiently. Operators should routinely check for wear and tear on the blades, as dull blades can lead to poor performance and increased energy consumption. Lubrication of moving parts is also essential to minimize friction and extend the lifespan of the machine. Additionally, it’s important to clean the machine thoroughly after use to prevent material build-up, which can cause blockages and impact machine efficiency.

Another critical aspect to consider is the installation of granulator machines. Proper installation is vital to avoid operational issues and ensure safety. Professionals should follow manufacturer guidelines closely, including electrical and mechanical connections. In some cases, it may be beneficial to engage technical support specialists during installation to ensure optimal setup and configuration.

Furthermore, understanding the specific material properties being processed can help in selecting the right granulator machine. Factors such as hardness, moisture content, and elasticity significantly influence the granulation process. Therefore, conducting a materials analysis can provide insights into the best machine settings, leading to enhanced product quality and operational efficiency.

In conclusion, granulator machines are essential tools in the mechanical equipment sector, facilitating the efficient processing of various materials. For professionals involved in the maintenance, installation, and technical support of these machines, understanding their operational principles and maintenance requirements is crucial. By prioritizing proper care and installation practices, you can ensure that your granulator machines remain reliable and effective for years to come.

At its core, a granulator operates by utilizing rotating blades to cut materials into smaller, more uniform pieces. The process begins when the raw material is fed into the machine, where the blades chop it down to the desired granule size. This process not only enhances the material's surface area but also facilitates easier handling and processing in downstream applications. Granulator machines are often equipped with adjustable screens that allow operators to control the particle size, making them versatile in their applications.

Regular maintenance is key to ensuring that granulator machines function efficiently. Operators should routinely check for wear and tear on the blades, as dull blades can lead to poor performance and increased energy consumption. Lubrication of moving parts is also essential to minimize friction and extend the lifespan of the machine. Additionally, it’s important to clean the machine thoroughly after use to prevent material build-up, which can cause blockages and impact machine efficiency.

Another critical aspect to consider is the installation of granulator machines. Proper installation is vital to avoid operational issues and ensure safety. Professionals should follow manufacturer guidelines closely, including electrical and mechanical connections. In some cases, it may be beneficial to engage technical support specialists during installation to ensure optimal setup and configuration.

Furthermore, understanding the specific material properties being processed can help in selecting the right granulator machine. Factors such as hardness, moisture content, and elasticity significantly influence the granulation process. Therefore, conducting a materials analysis can provide insights into the best machine settings, leading to enhanced product quality and operational efficiency.

In conclusion, granulator machines are essential tools in the mechanical equipment sector, facilitating the efficient processing of various materials. For professionals involved in the maintenance, installation, and technical support of these machines, understanding their operational principles and maintenance requirements is crucial. By prioritizing proper care and installation practices, you can ensure that your granulator machines remain reliable and effective for years to come.

Related Blog