The Ultimate Guide to Granulator Machine Maintenance for Optimal Performance

Release Time:

Sep 02,2025

The Ultimate Guide to Granulator Machine Maintenance for Optimal Performance Table of Contents Introduction to Granulator Machines Importance of Regular Maintenance Understanding Granulator Machine Components Creating a Maintenance Schedule Essential Routine Maintenance Tasks Troubleshooting Common Granulator Issues Best Practices for Granulator Machine Care Advanced Maintenance

The Ultimate Guide to Granulator Machine Maintenance for Optimal Performance

Table of Contents

- Introduction to Granulator Machines

- Importance of Regular Maintenance

- Understanding Granulator Machine Components

- Creating a Maintenance Schedule

- Essential Routine Maintenance Tasks

- Troubleshooting Common Granulator Issues

- Best Practices for Granulator Machine Care

- Advanced Maintenance Techniques for Efficiency

- Frequently Asked Questions

- Conclusion

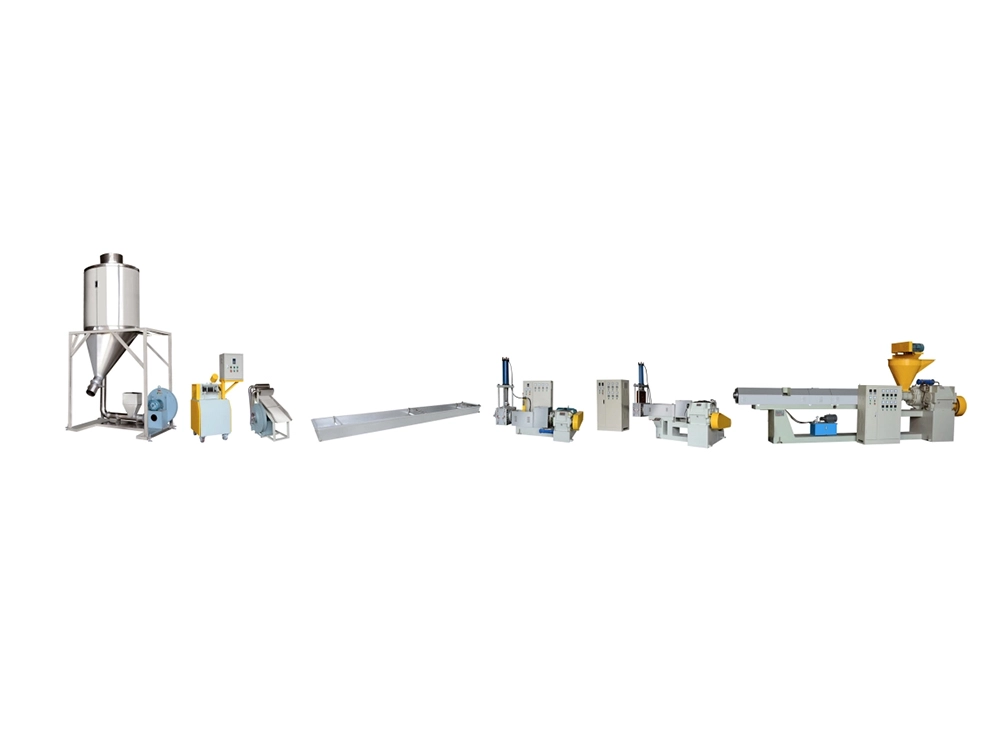

Introduction to Granulator Machines

Granulator machines play a crucial role in various industries, including recycling, plastics, and pharmaceuticals. Designed to break down materials into smaller, uniform particles, they enhance the efficiency of production processes. Proper maintenance of these machines is essential to ensure they operate at peak performance. This guide provides an in-depth look at the maintenance practices necessary for granulator machines, helping you achieve optimal efficiency and longevity.

Importance of Regular Maintenance

Regular maintenance of granulator machines is not just a recommendation; it's a necessity. Neglecting maintenance can lead to reduced performance, increased downtime, and higher operational costs. Key reasons for maintaining granulator machines include:

1. Enhanced Performance

Consistent maintenance ensures that all components function correctly, resulting in improved processing efficiency. This leads to better output quality and consistency.

2. Cost Efficiency

Regular maintenance can significantly reduce repair costs and prevent major breakdowns. By addressing minor issues before they escalate, businesses save money in the long run.

3. Extended Equipment Lifespan

Well-maintained granulator machines can last significantly longer than those that are not cared for. Routine checks and timely replacements of worn-out parts extend the machine's operational life.

4. Safety Compliance

Regular inspections and maintenance help ensure that equipment meets safety standards, reducing the risk of workplace accidents related to malfunctioning machinery.

Understanding Granulator Machine Components

To effectively maintain a granulator machine, it’s essential to understand its key components. Familiarity with these parts will enable you to perform targeted maintenance and troubleshooting.

1. Cutting Chamber

The cutting chamber houses the blades that shred materials. Regularly inspecting and sharpening these blades ensures they operate efficiently.

2. Feed Hopper

The feed hopper is where materials are loaded into the granulator. Ensuring it is clear of obstructions facilitates smooth operation.

3. Motor and Drive System

The motor powers the granulator, while the drive system ensures that the blades rotate at the correct speeds. Check for any signs of wear and tear in these components.

4. Screens and Mesh

Screens determine the size of the granulated output. Regular cleaning and replacement of worn screens are vital for maintaining particle size uniformity.

5. Discharge Chute

The discharge chute directs the granulated material out of the machine. Proper cleaning prevents blockages that can disrupt the operation.

Creating a Maintenance Schedule

Establishing a maintenance schedule is crucial for ensuring consistent upkeep of granulator machines. We recommend the following steps to create an effective schedule:

1. Daily Inspections

Performing daily checks on crucial components, such as the cutting chamber, blades, and feed hopper, helps identify issues early.

2. Weekly Maintenance

Weekly tasks should include cleaning the machine, checking for loose bolts, and inspecting belts for signs of wear.

3. Monthly Checks

Conduct more detailed inspections monthly. This should include thorough cleaning of the cutting chamber and motor checks.

4. Annual Overhaul

An annual comprehensive maintenance check is essential. Engage professional technicians to assess and perform necessary replacements or repairs.

Essential Routine Maintenance Tasks

Routine maintenance tasks are vital for keeping granulator machines operating efficiently. Here are some essential tasks to include in your maintenance routine:

1. Blade Sharpening and Replacement

Regularly sharpening blades enhances cutting efficiency. Replace blades when they become dull to prevent excessive wear on the motor.

2. Cleaning and Lubrication

Keeping the machine clean and lubricated is crucial. Use appropriate lubricants on moving parts to prevent friction and wear.

3. Checking Electrical Connections

Inspecting electrical connections for signs of wear or corrosion can prevent unexpected failures. Ensure all connections are secure.

4. Monitoring for Vibration

Excessive vibration can indicate misalignment or wear. Regular monitoring helps catch issues early, preventing further damage.

Troubleshooting Common Granulator Issues

Despite best maintenance practices, issues may still arise. Understanding how to troubleshoot common problems can save time and resources.

1. Overheating

If the granulator is overheating, check for blockages in the feed hopper and discharge chute. Ensure that the motor and drive system are functioning correctly.

2. Inconsistent Output Size

Inconsistent granule size may be due to worn blades or damaged screens. Regularly inspect and replace these components as necessary.

3. Unusual Noises

Strange noises may indicate internal wear or misalignment. Stop the machine immediately and conduct a thorough inspection to identify the cause.

Best Practices for Granulator Machine Care

Implementing best practices can greatly enhance the longevity and efficiency of granulator machines. Consider the following recommendations:

1. Operator Training

Ensure that operators are well-trained in the operation and maintenance of granulator machines. Proper training helps prevent operational errors that can lead to damage.

2. Use Quality Materials

Using high-quality materials lessens wear on the granulator and leads to a more efficient processing operation.

3. Document Maintenance Activities

Keep detailed records of maintenance activities, including dates, tasks performed, and any issues encountered. This helps in tracking the machine's performance over time.

4. Invest in Quality Parts

When replacements are necessary, invest in high-quality parts. Cheaper alternatives may lead to more frequent breakdowns and higher long-term costs.

Advanced Maintenance Techniques for Efficiency

For those looking to optimize their maintenance strategies, consider implementing these advanced techniques:

1. Predictive Maintenance

Utilizing sensors and monitoring technologies can help predict when maintenance is required, allowing for proactive rather than reactive measures.

2. Vibration Analysis

Conducting vibration analysis can help identify issues with bearings and other components before they cause significant problems.

3. Thermal Imaging

Using thermal imaging technology can reveal overheating components, allowing for targeted interventions before failures occur.

Frequently Asked Questions

1. How often should I perform maintenance on my granulator machine?

Maintenance should be conducted daily, weekly, monthly, and annually as outlined in your maintenance schedule.

2. What are the signs that my granulator machine needs maintenance?

Signs include unusual noises, overheating, reduced output quality, and excessive vibrations.

3. Can I perform maintenance myself, or should I hire a professional?

Routine maintenance tasks can typically be performed in-house, but for major repairs or overhauls, professional technicians are recommended.

4. What type of lubrication should I use for my granulator machine?

Always refer to the manufacturer's guidelines for recommended lubricants to ensure optimal performance and protection.

5. How can I improve the lifespan of my granulator machine?

Regular maintenance, using quality parts, and ensuring operator training are key factors in extending the lifespan of your granulator machine.

Conclusion

Maintaining a granulator machine is essential for optimal performance, cost-effectiveness, and safety in the workplace. By implementing a structured maintenance schedule, performing routine tasks diligently, and embracing advanced techniques, businesses can maximize the efficiency and lifespan of their granulator machines. Prioritizing regular maintenance not only enhances productivity but also contributes to a safer and more sustainable operational environment. Following the guidelines outlined in this comprehensive guide will ensure that your granulator machine operates at its best for years to come.

Related Blog