Understanding Granulator Machines: Essential Insights for Effective Operation

Release Time:

Aug 28,2025

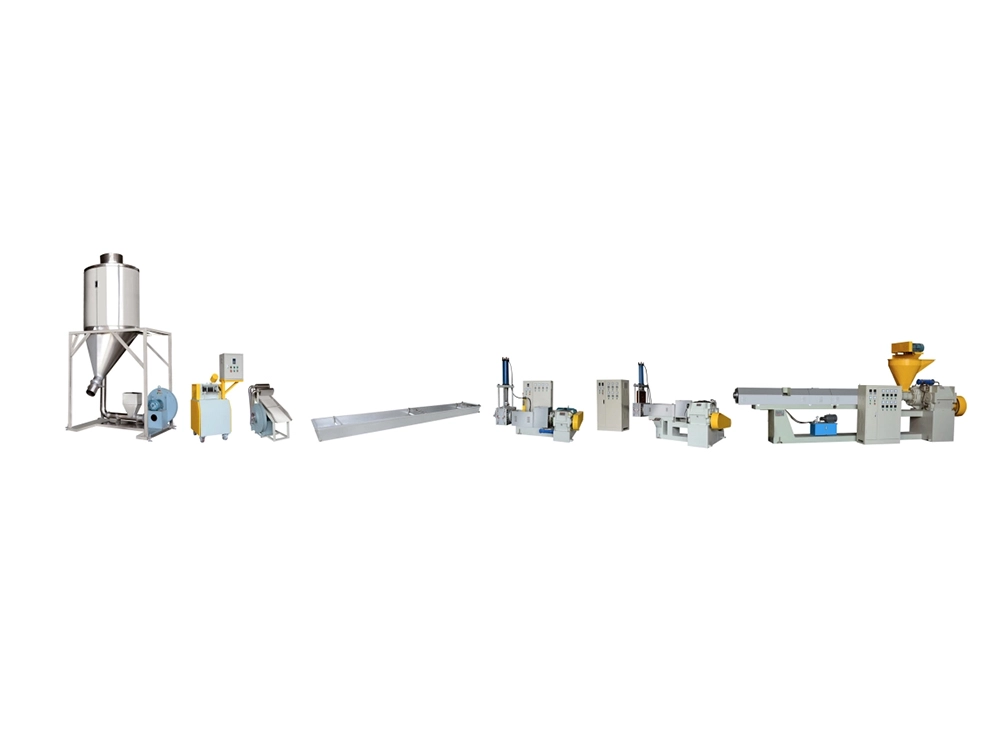

Granulator machines play a pivotal role in various industries, especially in the processing of plastics, pharmaceuticals, and food products. These machines are designed to reduce large materials into smaller, uniform particles or granules, facilitating easier handling, processing, and recycling. Understanding the mechanics behind granulator machines can greatly enhance their operational efficiency

Granulator machines play a pivotal role in various industries, especially in the processing of plastics, pharmaceuticals, and food products. These machines are designed to reduce large materials into smaller, uniform particles or granules, facilitating easier handling, processing, and recycling. Understanding the mechanics behind granulator machines can greatly enhance their operational efficiency and longevity, which is crucial for businesses that rely on them.

The primary function of a granulator machine is to take bulk materials, such as plastic sheets, film, or rejects, and shred them into smaller pieces. This process not only makes the material easier to handle but also prepares it for further processing, such as recycling or manufacturing. Granulators are equipped with sharp blades and screens that determine the size of the output granules. This capability allows businesses to customize the granule size according to their specific requirements.

Granulator machines find applications in various sectors. In the plastic industry, they facilitate the recycling of scrap plastic, contributing to sustainability efforts by reducing waste. In the pharmaceutical sector, granulators ensure uniform particle size for medication, which is crucial for dosage accuracy. The food industry also utilizes granulators to process ingredients into granulated forms for easier mixing and packaging.

Maintenance of granulator machines is essential to ensure optimal performance and longevity. Regular inspections of the blades, screens, and motor are vital. Dull blades can result in inefficient grinding and increased energy consumption, while worn-out screens can lead to inconsistent granule sizes. Additionally, checking for any mechanical wear and tear can prevent unexpected breakdowns, allowing for smooth operation and minimizing downtime.

Moreover, it's important to consider the feeding mechanism of the granulator machine. An efficient feeding system ensures a consistent flow of material, which is crucial for maintaining the machine's performance. Overloading the machine can lead to jams and increased wear on the components, while underfeeding can result in empty runs and decreased efficiency.

In summary, granulator machines are indispensable in various industries for their ability to efficiently reduce materials into manageable sizes. Understanding their operation, applications, and maintenance needs can significantly impact the overall efficiency and effectiveness of your operations. Whether you are involved in mechanical equipment repair or installation, having a thorough comprehension of granulator machines will enable you to provide better support and services, ensuring that these machines operate at their best.

The primary function of a granulator machine is to take bulk materials, such as plastic sheets, film, or rejects, and shred them into smaller pieces. This process not only makes the material easier to handle but also prepares it for further processing, such as recycling or manufacturing. Granulators are equipped with sharp blades and screens that determine the size of the output granules. This capability allows businesses to customize the granule size according to their specific requirements.

Granulator machines find applications in various sectors. In the plastic industry, they facilitate the recycling of scrap plastic, contributing to sustainability efforts by reducing waste. In the pharmaceutical sector, granulators ensure uniform particle size for medication, which is crucial for dosage accuracy. The food industry also utilizes granulators to process ingredients into granulated forms for easier mixing and packaging.

Maintenance of granulator machines is essential to ensure optimal performance and longevity. Regular inspections of the blades, screens, and motor are vital. Dull blades can result in inefficient grinding and increased energy consumption, while worn-out screens can lead to inconsistent granule sizes. Additionally, checking for any mechanical wear and tear can prevent unexpected breakdowns, allowing for smooth operation and minimizing downtime.

Moreover, it's important to consider the feeding mechanism of the granulator machine. An efficient feeding system ensures a consistent flow of material, which is crucial for maintaining the machine's performance. Overloading the machine can lead to jams and increased wear on the components, while underfeeding can result in empty runs and decreased efficiency.

In summary, granulator machines are indispensable in various industries for their ability to efficiently reduce materials into manageable sizes. Understanding their operation, applications, and maintenance needs can significantly impact the overall efficiency and effectiveness of your operations. Whether you are involved in mechanical equipment repair or installation, having a thorough comprehension of granulator machines will enable you to provide better support and services, ensuring that these machines operate at their best.

Related Blog