Unlocking Efficiency: How a Granulator Machine Revolutionizes Your Production

Release Time:

Aug 23,2025

Unlocking Efficiency: How a Granulator Machine Revolutionizes Your Production Introduction to Granulator Machines In the ever-evolving landscape of manufacturing and production, efficiency is the name of the game. As industries strive to optimize their processes, **granulator machines** have emerged as pivotal players in enhancing productivity and reducing waste. These powerful machines excel at t

Unlocking Efficiency: How a Granulator Machine Revolutionizes Your Production

Introduction to Granulator Machines

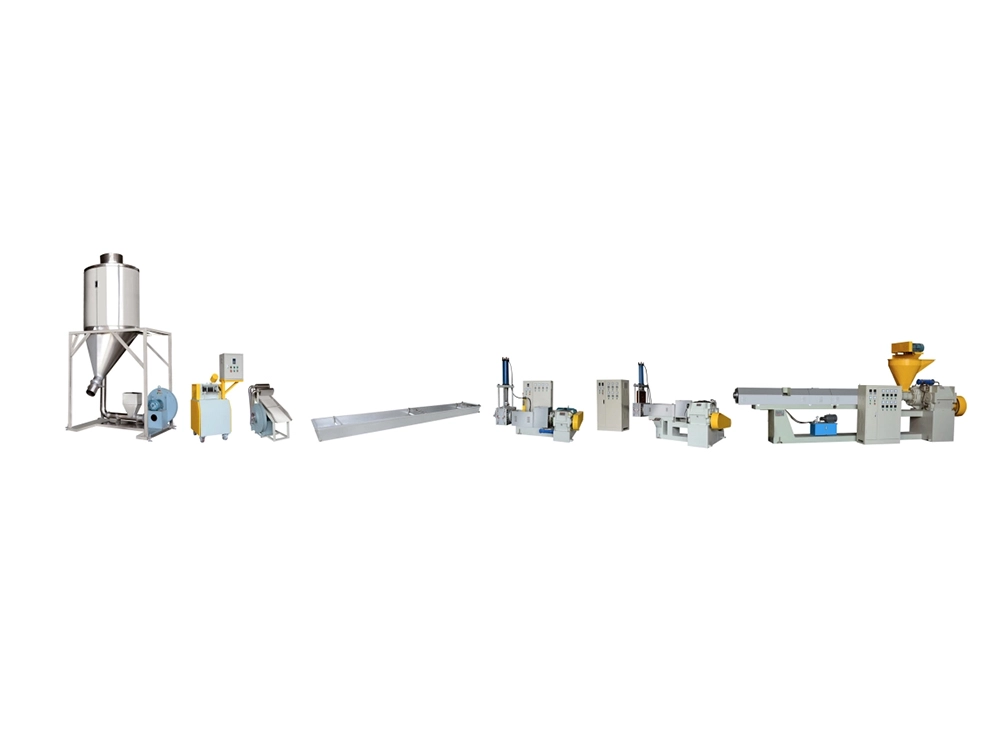

In the ever-evolving landscape of manufacturing and production, efficiency is the name of the game. As industries strive to optimize their processes, **granulator machines** have emerged as pivotal players in enhancing productivity and reducing waste. These powerful machines excel at transforming raw materials into uniform granules, paving the way for streamlined operations. This article delves into the workings of granulator machines, their myriad applications, and how they can revolutionize your production setup.

What is a Granulator Machine?

A granulator machine is a specialized piece of equipment designed to break down materials into smaller, manageable granules. Usually used in industries such as plastics, pharmaceuticals, and food processing, granulators facilitate easy handling, storage, and further processing of materials. By producing uniform granules, these machines ensure consistent quality and optimize the production line's efficiency.

How Granulator Machines Work

Understanding the operation of granulator machines is crucial for realizing their potential. Here’s how they function:

1. **Material Feeding**: Raw materials are fed into the granulator's hopper, where they are prepared for processing.

2. **Size Reduction**: The materials are then subjected to cutting and grinding through rotating blades or knives. This action reduces the materials into smaller particle sizes.

3. **Granulation**: The resulting particles are shaped into granules, achieving a consistent size that is ideal for subsequent processing.

4. **Collection**: Finally, the granules are collected for packaging or sent directly to the next stage of production.

The Importance of Granulation in Manufacturing

Granulation serves several essential purposes in manufacturing:

Consistency in Product Quality

Uniform granules ensure that products meet specific quality standards. In industries like pharmaceuticals, consistent granule sizes are critical for accurate dosing and efficacy.

Improved Flowability

Granulated materials flow more easily than powders, reducing the risk of clogging in processing equipment and ensuring smooth operation.

Enhanced Solubility

In the food and pharmaceutical industries, granulation can improve the solubility of active ingredients, making them more effective and faster acting.

Types of Granulator Machines

Granulator machines come in various forms, each tailored to meet specific processing needs. Common types include:

Cutter Granulators

These machines utilize sharp blades to cut materials into granules. They are particularly effective for plastics and rubber.

Wet Granulators

Wet granulation involves adding a liquid binder to the mix, enhancing particle cohesion and improving flow properties. This method is commonly used in the pharmaceutical industry.

Dry Granulators

Ideal for sensitive materials, dry granulators compress powders into larger granules without the need for liquid binders. This process is essential for heat-sensitive ingredients.

Applications of Granulator Machines

The versatility of granulator machines allows for widespread application across various industries:

Pharmaceutical Industry

Granulators in the pharmaceutical sector ensure precise granule sizes for medications, enhancing bioavailability and effectiveness. The consistent quality achieved through granulation is paramount for regulatory compliance.

Plastics and Polymers

In the plastics industry, granulators recycle scrap materials, turning them into usable granules that can be reprocessed, contributing to sustainability.

Food Processing

Granulation in food processing improves mixing and ensures even distribution of ingredients, vital for product quality and safety.

The Benefits of Integrating Granulator Machines in Your Production Line

Investing in a granulator machine offers numerous advantages that can transform your production capabilities:

Increased Efficiency

Granulator machines streamline the production process, reducing the time and labor required to prepare materials. This efficiency translates into higher output and lower operational costs.

Waste Reduction

By converting scrap materials into usable granules, granulators minimize waste and maximize resource utilization, promoting sustainable practices.

Enhanced Product Quality

The ability to produce uniform granules ensures consistent product quality, meeting customer expectations and enhancing brand reputation.

Cost-Effective Operations

While the initial investment in a granulator machine may seem substantial, the long-term savings through reduced waste and improved efficiency often outweigh the costs.

Choosing the Right Granulator Machine for Your Needs

Selecting the appropriate granulator machine requires careful consideration of several factors:

Material Type

Different materials require specific granulator types. Assess the properties of your materials before making a selection.

Production Volume

Consider your production scale. High-volume operations may benefit from larger, more robust granulators that can handle increased loads.

Space and Layout

Evaluate your facility's layout and available space. A compact granulator may be more suitable for smaller operations, while larger facilities may accommodate bulkier machines.

Maintenance Tips for Granulator Machines

Proper maintenance is crucial for the longevity and performance of granulator machines. Here are some essential tips:

Regular Cleaning

Keep the machine clean to prevent material buildup, which can affect performance and product quality.

Routine Inspections

Regularly inspect blades and other moving parts for wear and tear. Timely replacements can prevent breakdowns.

Lubrication and Calibration

Ensure that all moving parts are adequately lubricated to minimize friction and maintain optimal performance.

Common Challenges and Solutions in Granulation

While granulation offers numerous benefits, manufacturers may encounter challenges:

Inconsistent Granule Size

If granule sizes vary significantly, consider adjusting the machine settings or the material feeding rate to maintain consistency.

Material Clogging

Material clogging can be addressed by optimizing the feeding system and ensuring proper machine operation protocols are followed.

Future Trends in Granulation Technology

As technology advances, the granulation process continues to evolve. Here are some trends to watch:

Smart Granulation Systems

The integration of AI and IoT in granulation systems allows for real-time monitoring and adjustments, enhancing efficiency and reducing errors.

Sustainable Granulation Practices

Focus on sustainability is leading to innovations in eco-friendly materials and processes, further promoting waste reduction and resource efficiency.

FAQs

1. What materials can be processed with a granulator machine?

Granulator machines can handle a wide range of materials, including plastics, rubber, pharmaceuticals, and food products.

2. How do I know what type of granulator machine I need?

Consider the material properties, production volume, and available space in your facility when selecting a granulator machine.

3. What is the difference between wet and dry granulation?

Wet granulation involves adding a liquid binder to create cohesive granules, while dry granulation compresses powders into granules without liquids.

4. What maintenance does a granulator machine require?

Regular cleaning, inspections, lubrication, and calibration are essential for maintaining a granulator machine.

5. Can granulator machines help reduce production waste?

Yes, granulator machines convert scrap materials into usable granules, significantly minimizing waste and promoting sustainability.

Conclusion

Granulator machines stand at the forefront of modern manufacturing, offering a powerful solution to enhance efficiency and product quality. By integrating granulation technology into your production processes, you can streamline operations, reduce waste, and ensure consistent product quality. As industries continue to prioritize efficiency and sustainability, investing in the right granulator machine becomes not just advantageous, but essential for long-term success. Embrace this innovation and unlock new levels of efficiency in your production line today.

Related Blog