Understanding the Role of Plastic Granulator Machines in Industrial Recycling

Release Time:

Aug 18,2025

Plastic granulator machines play a pivotal role in the recycling industry, particularly in the processing of plastic waste. These machines are designed to reduce plastic materials into smaller granules or pellets, which can then be reused in manufacturing processes. This not only aids in waste reduction but also enhances the sustainability of the materials used in various industries. The operation

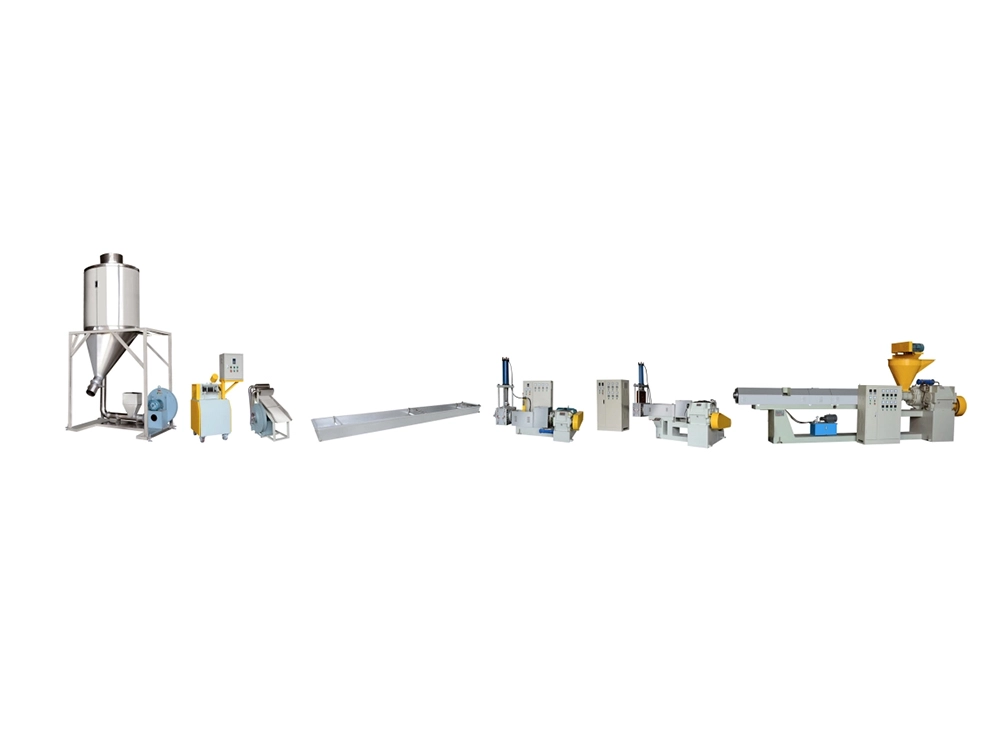

Plastic granulator machines play a pivotal role in the recycling industry, particularly in the processing of plastic waste. These machines are designed to reduce plastic materials into smaller granules or pellets, which can then be reused in manufacturing processes. This not only aids in waste reduction but also enhances the sustainability of the materials used in various industries.

The operation of a plastic granulator machine typically involves feeding plastic waste into a hopper, where it is then conveyed into a cutting chamber. Here, rotating blades chop the plastic into smaller pieces, which are later processed through a screening system that ensures uniform granule size. The granulated plastic can then be repurposed for manufacturing new plastic products, thereby closing the loop in plastic usage and reducing the need for virgin materials.

One of the key advantages of using a plastic granulator machine is the efficiency it brings to the recycling process. By converting large volumes of plastic waste into manageable granules, these machines facilitate easier transportation and processing of materials. Moreover, the granulation process enhances the quality of the recycled material, making it more suitable for reuse in various applications.

In addition to their operational benefits, proper maintenance and technical support for plastic granulator machines are crucial. Regular maintenance checks can help identify potential issues early and ensure the machine operates at peak efficiency. This not only prolongs the lifespan of the equipment but also minimizes downtime, which can be a significant cost factor in industrial operations. Technical support services can provide valuable assistance in troubleshooting, repairs, and optimizing machine settings for different types of plastic materials.

Furthermore, understanding the different types of plastic granulator machines available in the market can aid businesses in selecting the right model for their specific needs. There are various configurations available, ranging from small-scale machines suitable for local recycling initiatives to larger industrial models designed for high-volume operations. Factors to consider include the types of plastic being processed, the desired granule size, and the overall production capacity required.

In conclusion, plastic granulator machines are an essential component of modern recycling practices, offering significant benefits in terms of efficiency and sustainability. By investing in proper maintenance and technical support, businesses can maximize the performance of these machines, ultimately contributing to a more circular economy and a greener future. Understanding how to effectively utilize and maintain these machines can lead to improved recycling outcomes and a reduction in plastic waste in our environment.

The operation of a plastic granulator machine typically involves feeding plastic waste into a hopper, where it is then conveyed into a cutting chamber. Here, rotating blades chop the plastic into smaller pieces, which are later processed through a screening system that ensures uniform granule size. The granulated plastic can then be repurposed for manufacturing new plastic products, thereby closing the loop in plastic usage and reducing the need for virgin materials.

One of the key advantages of using a plastic granulator machine is the efficiency it brings to the recycling process. By converting large volumes of plastic waste into manageable granules, these machines facilitate easier transportation and processing of materials. Moreover, the granulation process enhances the quality of the recycled material, making it more suitable for reuse in various applications.

In addition to their operational benefits, proper maintenance and technical support for plastic granulator machines are crucial. Regular maintenance checks can help identify potential issues early and ensure the machine operates at peak efficiency. This not only prolongs the lifespan of the equipment but also minimizes downtime, which can be a significant cost factor in industrial operations. Technical support services can provide valuable assistance in troubleshooting, repairs, and optimizing machine settings for different types of plastic materials.

Furthermore, understanding the different types of plastic granulator machines available in the market can aid businesses in selecting the right model for their specific needs. There are various configurations available, ranging from small-scale machines suitable for local recycling initiatives to larger industrial models designed for high-volume operations. Factors to consider include the types of plastic being processed, the desired granule size, and the overall production capacity required.

In conclusion, plastic granulator machines are an essential component of modern recycling practices, offering significant benefits in terms of efficiency and sustainability. By investing in proper maintenance and technical support, businesses can maximize the performance of these machines, ultimately contributing to a more circular economy and a greener future. Understanding how to effectively utilize and maintain these machines can lead to improved recycling outcomes and a reduction in plastic waste in our environment.

Related Blog