The Vital Role of Plastic Recycling Granulator Machines in Sustainable Manufacturing

Release Time:

Oct 17,2025

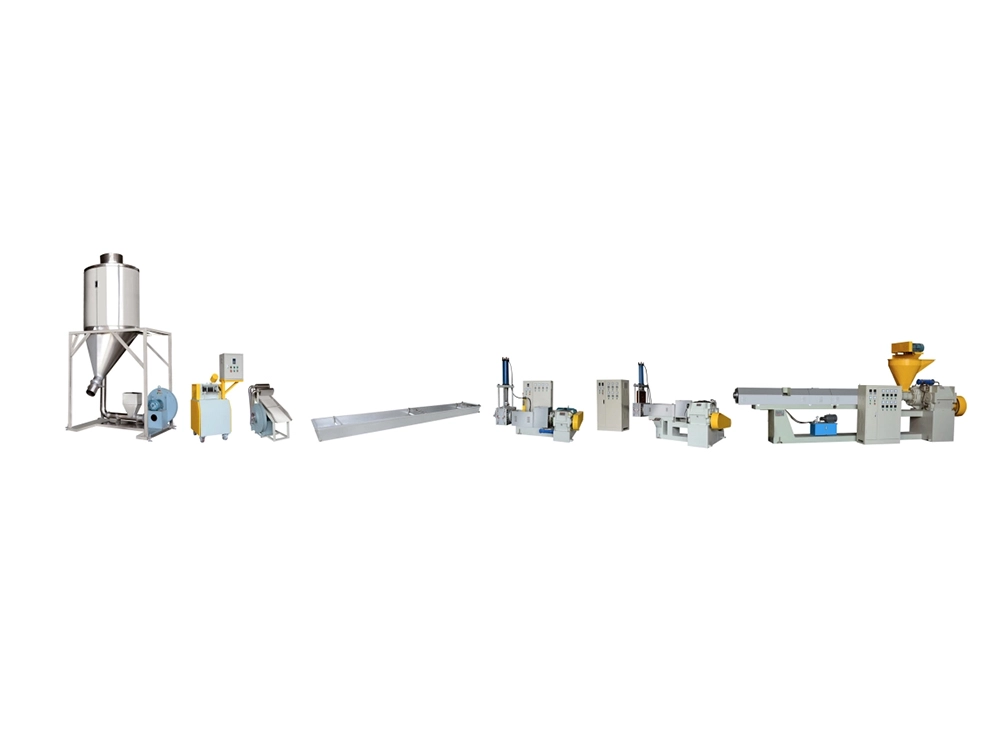

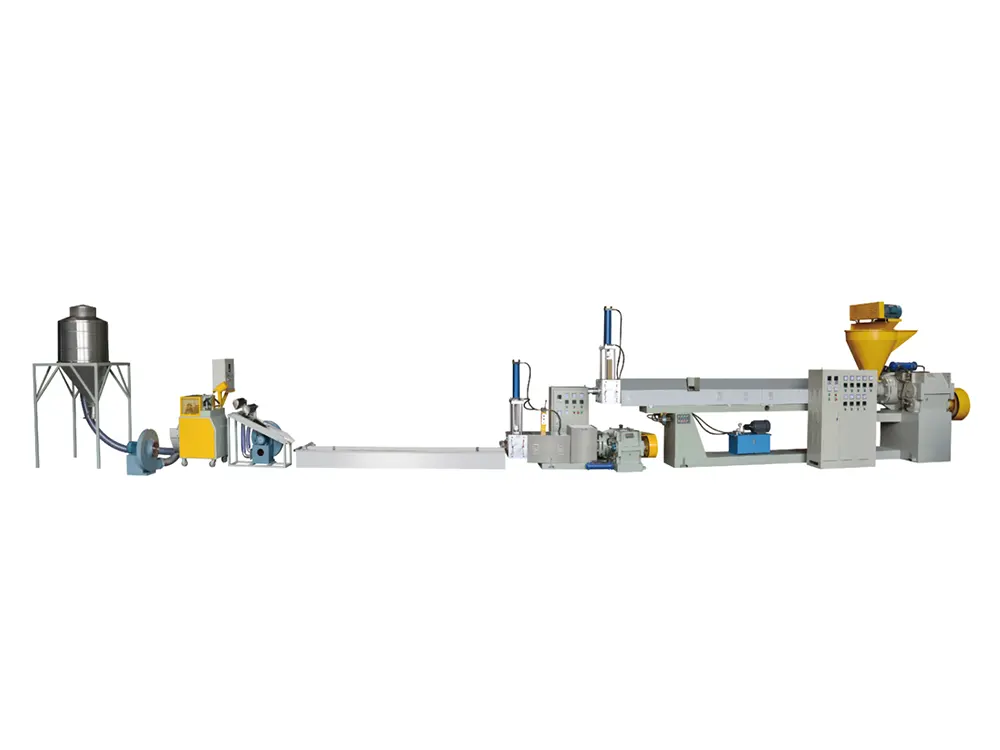

Plastic recycling granulator machines play an essential role in the modern manufacturing landscape, especially as industries seek to adopt more sustainable practices. These machines are designed to process plastic waste, transforming it into usable granules that can be reintroduced into the production cycle. This not only reduces the amount of plastic that ends up in landfills but also conserves n

Plastic recycling granulator machines play an essential role in the modern manufacturing landscape, especially as industries seek to adopt more sustainable practices. These machines are designed to process plastic waste, transforming it into usable granules that can be reintroduced into the production cycle. This not only reduces the amount of plastic that ends up in landfills but also conserves natural resources and energy, aligning with the principles of a circular economy.

At the core of their functionality, plastic recycling granulator machines utilize a series of cutting blades and screens to shred and grind plastic waste into small particles. This process involves heating the plastic to its melting point, allowing it to be formed into granules. The resulting material can then be used in various manufacturing processes, creating new products from recycled materials. This not only promotes sustainability but also offers manufacturers a cost-effective alternative to virgin plastic materials.

One of the significant benefits of utilizing a plastic recycling granulator machine is the reduction of environmental impact. By recycling plastics, companies can significantly lower their carbon footprint, minimize pollution, and conserve natural resources. This is increasingly important as consumers and regulatory bodies demand more environmentally friendly practices from manufacturers. Adopting such technologies can enhance a company's reputation and appeal to eco-conscious customers.

Moreover, the efficiency of plastic recycling granulator machines contributes to streamlined operations within manufacturing facilities. These machines are designed for durability and high throughput, allowing businesses to process large volumes of plastic waste quickly. This efficiency not only saves time but also reduces operational costs associated with waste disposal and material procurement.

Additionally, integrating plastic recycling granulator machines into existing operations can provide substantial technical advantages. With appropriate maintenance and support, these machines can operate seamlessly, ensuring consistent output quality. Businesses must invest in regular servicing and technical support to maximize the lifespan and efficiency of their equipment, which in turn can lead to greater financial savings over time.

In the context of mechanical equipment maintenance, installation, and support services, it is crucial for companies to partner with service providers that understand the intricacies of plastic recycling granulator machines. Proper installation ensures optimal performance, while ongoing technical support helps address any operational challenges that may arise.

In conclusion, plastic recycling granulator machines are invaluable assets for manufacturers striving to reduce waste and promote sustainability. By transforming plastic waste into reusable granules, these machines not only help in preserving the environment but also enhance operational efficiency and cost-effectiveness. As the industry continues to evolve towards greener practices, the significance of implementing such innovative technologies will only grow.

At the core of their functionality, plastic recycling granulator machines utilize a series of cutting blades and screens to shred and grind plastic waste into small particles. This process involves heating the plastic to its melting point, allowing it to be formed into granules. The resulting material can then be used in various manufacturing processes, creating new products from recycled materials. This not only promotes sustainability but also offers manufacturers a cost-effective alternative to virgin plastic materials.

One of the significant benefits of utilizing a plastic recycling granulator machine is the reduction of environmental impact. By recycling plastics, companies can significantly lower their carbon footprint, minimize pollution, and conserve natural resources. This is increasingly important as consumers and regulatory bodies demand more environmentally friendly practices from manufacturers. Adopting such technologies can enhance a company's reputation and appeal to eco-conscious customers.

Moreover, the efficiency of plastic recycling granulator machines contributes to streamlined operations within manufacturing facilities. These machines are designed for durability and high throughput, allowing businesses to process large volumes of plastic waste quickly. This efficiency not only saves time but also reduces operational costs associated with waste disposal and material procurement.

Additionally, integrating plastic recycling granulator machines into existing operations can provide substantial technical advantages. With appropriate maintenance and support, these machines can operate seamlessly, ensuring consistent output quality. Businesses must invest in regular servicing and technical support to maximize the lifespan and efficiency of their equipment, which in turn can lead to greater financial savings over time.

In the context of mechanical equipment maintenance, installation, and support services, it is crucial for companies to partner with service providers that understand the intricacies of plastic recycling granulator machines. Proper installation ensures optimal performance, while ongoing technical support helps address any operational challenges that may arise.

In conclusion, plastic recycling granulator machines are invaluable assets for manufacturers striving to reduce waste and promote sustainability. By transforming plastic waste into reusable granules, these machines not only help in preserving the environment but also enhance operational efficiency and cost-effectiveness. As the industry continues to evolve towards greener practices, the significance of implementing such innovative technologies will only grow.

Related Blog