How to Choose the Right Plastic Recycling Granulator Machine for Your Needs

Release Time:

Oct 12,2025

How to Choose the Right Plastic Recycling Granulator Machine for Your Needs Table of Contents Understanding Plastic Recycling Granulators Importance of Selecting the Right Machine Key Factors to Consider When Choosing a Granulator Machine Capacity and Throughput Material Type and Size Granulator Design and Configurations Energy

How to Choose the Right Plastic Recycling Granulator Machine for Your Needs

Table of Contents

- Understanding Plastic Recycling Granulators

- Importance of Selecting the Right Machine

- Key Factors to Consider When Choosing a Granulator

- Machine Capacity and Throughput

- Material Type and Size

- Granulator Design and Configurations

- Energy Efficiency and Cost

- How to Evaluate Manufacturers and Suppliers

- Maintenance and Support Considerations

- Sustainable Practices in Recycling

- Future Trends in Plastic Recycling

- FAQs

Understanding Plastic Recycling Granulators

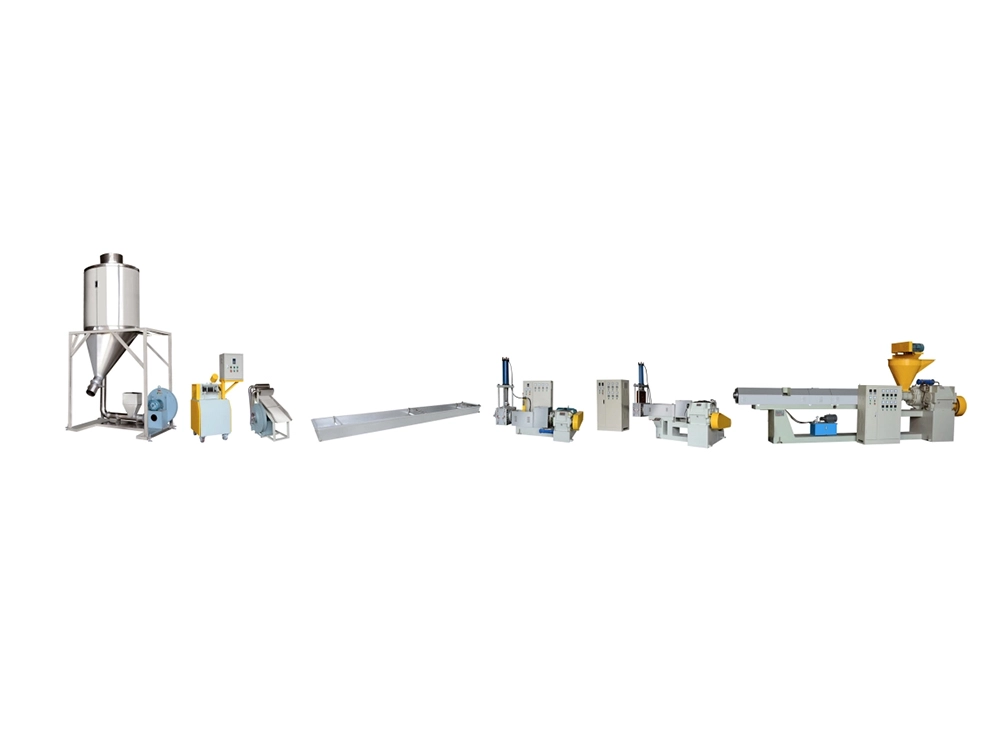

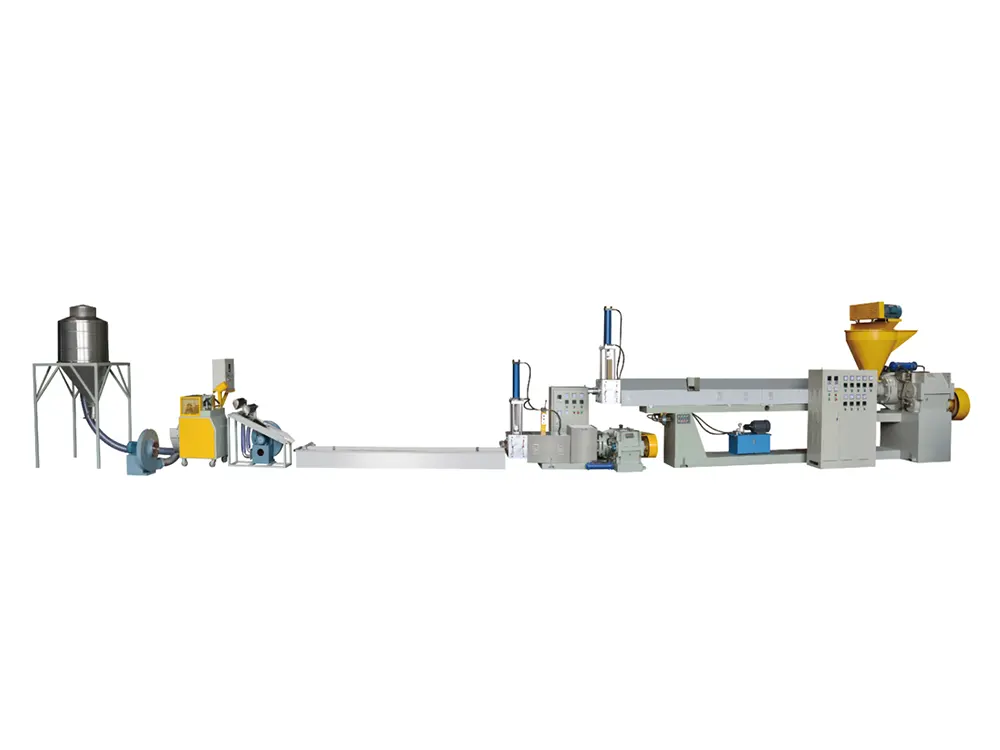

Plastic recycling granulators serve as essential machinery in the waste management sector, converting plastic waste into reusable granules. These granules can then be reprocessed into new products, contributing to sustainable practices and reducing environmental impact. Understanding the mechanics and functionality of these machines is the first step in ensuring you choose the right one for your operations.

Importance of Selecting the Right Machine

Choosing the appropriate plastic recycling granulator machine directly influences the efficiency and effectiveness of your recycling processes. A well-suited machine enhances productivity, reduces operational costs, and improves the quality of the output granules. Therefore, investing time and effort into selecting the right granulator is paramount for any recycling operation.

Key Factors to Consider When Choosing a Granulator

When navigating the market for plastic recycling granulators, several critical factors come into play. Understanding these elements can significantly impact your decision.

Machine Capacity and Throughput

The capacity of the granulator defines how much material it can process in a given time frame. When evaluating machine capacity, consider your operation's volume of plastic waste. Higher throughput machines are ideal for large-scale operations, whereas smaller units may suffice for lower volumes. It's essential to match the granulator's capacity with your production targets to avoid bottlenecks.

Material Type and Size

Different types of plastics possess varying characteristics and processing needs. Consider the types of plastic waste you'll be recycling—common materials include PET, HDPE, and LDPE. Additionally, the size of the input materials should be assessed; some granulators feature adjustable knife settings to accommodate different sizes, providing versatility in handling various waste forms.

Granulator Design and Configurations

The design of the granulator affects its efficiency and ease of use. Key design features to evaluate include the rotor speed, knife configuration, and screen size. Machines with variable rotor speeds allow for better control over the shredding process, while specific knife arrangements can optimize the granulation of particular materials. Also, consider whether you need a standalone unit or a machine that can integrate into existing lines.

Energy Efficiency and Cost

Energy consumption is a crucial consideration. An energy-efficient granulator not only reduces operational costs but also aligns with environmentally sustainable practices. When evaluating costs, consider both the initial purchase price and the long-term operational costs, including maintenance and energy use. Balancing upfront investment with efficiency gains is key to making a sound financial decision.

How to Evaluate Manufacturers and Suppliers

Choosing the right manufacturer is as important as selecting the granulator itself. Look for suppliers with a proven track record in the industry and positive customer reviews. Request references and check for certifications that demonstrate quality and reliability. Engaging with manufacturers who offer clear after-sales support, spare parts availability, and warranties can also enhance your purchasing experience.

Maintenance and Support Considerations

Regular maintenance is essential to ensure the longevity and optimal performance of your granulator. Consider the ease of maintenance when selecting a machine; some models are designed for quick access to key components, simplifying the upkeep process. Additionally, evaluate the level of technical support the manufacturer provides. Reliable customer service can significantly reduce downtime and enhance operational efficiency.

Sustainable Practices in Recycling

Sustainability is at the forefront of modern recycling efforts. Selecting a granulator that aligns with sustainable practices can enhance your brand's eco-friendly image. Consider machines that reduce waste and energy consumption while maximizing the reuse of materials. Incorporating sustainable practices not only meets regulatory requirements but also appeals to environmentally conscious customers.

Future Trends in Plastic Recycling

The landscape of plastic recycling is continually evolving. Innovations in technology, such as advanced sorting systems and AI-driven analytics, are shaping the future of recycling operations. Stay informed about trends that may impact your choice of granulator. For instance, the rise of biodegradable plastics and the increasing demand for recycled materials are driving the need for more specialized granulation technology.

FAQs

1. What is a plastic recycling granulator machine?

A plastic recycling granulator machine is designed to break down plastic waste into smaller granules, making it easier to recycle and reuse in the production of new plastic products.

2. How do I know what capacity granulator I need?

Assess your operational volume of plastic waste and match it with the granulator's capacity. Higher throughput machines are suited for larger operations, while smaller units may suffice for lower volumes.

3. Are there specific granulators for different types of plastics?

Yes, different granulators are designed to handle various plastics. It's essential to choose a machine that accommodates the specific types of plastic you will be recycling.

4. How often should I maintain my granulator?

Regular maintenance is crucial for optimal performance. Follow the manufacturer's recommendations for maintenance schedules, which may vary depending on usage.

5. What are the benefits of energy-efficient granulators?

Energy-efficient granulators minimize operational costs and environmental impact, making them a sustainable choice for recycling operations.

Conclusion

Choosing the right plastic recycling granulator machine is a multifaceted decision that requires careful consideration of various factors, including capacity, material types, design features, and energy efficiency. By understanding these elements and evaluating manufacturers thoroughly, you can make an informed choice that enhances your recycling operations. Emphasizing sustainable practices can further improve your business's environmental footprint and market appeal. As the industry evolves, staying updated on trends and technologies will ensure that you remain competitive and capable of meeting the demands of the recycling market.

Related Blog