Understanding Different Types of EVA Plastic Recycling Services: A Comprehensive Guide

Release Time:

Jun 06,2025

Understanding Different Types of EVA Plastic Recycling Services Table of Contents 1. What is EVA Plastic? 2. Importance of Recycling EVA Plastic 3. Types of EVA Plastic Recycling Services 3.1 Mechanical Recycling 3.2 Chemical Recycling 3.3 Energy Recovery 4. Benefits of EVA Plastic Recycling 5. How to Choose the Right EVA Recycling Service 6. The EVA Recycling Process Explained 7. Challenges in EV

Understanding Different Types of EVA Plastic Recycling Services

Table of Contents

1. What is EVA Plastic?

2. Importance of Recycling EVA Plastic

3. Types of EVA Plastic Recycling Services

3.1 Mechanical Recycling

3.2 Chemical Recycling

3.3 Energy Recovery

4. Benefits of EVA Plastic Recycling

5. How to Choose the Right EVA Recycling Service

6. The EVA Recycling Process Explained

7. Challenges in EVA Plastic Recycling

8. Future of EVA Plastic Recycling

9. Frequently Asked Questions (FAQs)

10. Conclusion

1. What is EVA Plastic?

EVA, or ethylene-vinyl acetate, is a type of plastic that is widely used in various applications due to its flexibility, transparency, and resistance to UV radiation. It is commonly found in products like foam padding, sports equipment, and packaging materials. The unique properties of EVA make it an ideal choice for many industries, contributing to its popularity.

2. Importance of Recycling EVA Plastic

Recycling EVA plastic is crucial in today's environmental landscape. With growing concerns over plastic pollution, the recycling of materials like EVA can significantly reduce waste in landfills and oceans. By recycling EVA, we not only conserve natural resources but also reduce energy consumption in producing new plastic materials. This creates a circular economy where materials are reused, minimizing environmental impact.

3. Types of EVA Plastic Recycling Services

Understanding the different types of EVA plastic recycling services is vital for making informed choices. Here are the primary services available in the market:

3.1 Mechanical Recycling

Mechanical recycling is the most common type of recycling for EVA plastic. This process involves collecting, cleaning, and shredding used EVA materials into smaller pieces. These pieces are then melted and reformed into new products. Mechanical recycling is efficient, cost-effective, and requires less energy compared to other recycling methods.

3.2 Chemical Recycling

Chemical recycling, also known as advanced recycling, involves breaking down EVA into its basic chemical components through processes like pyrolysis or depolymerization. This method allows for the recycling of materials that may not be suitable for mechanical recycling. The resulting chemicals can be used to produce new EVA or other types of plastics, further extending the life cycle of the material.

3.3 Energy Recovery

Energy recovery is an alternative recycling method that focuses on converting EVA waste into energy rather than reusing it as a material. This process involves incinerating EVA plastic in controlled environments to generate electricity or heat. While not a traditional recycling method, energy recovery plays a role in waste-to-energy initiatives and can help mitigate the volume of waste.

4. Benefits of EVA Plastic Recycling

Recycling EVA plastic offers a range of benefits, both environmentally and economically. Here are some key advantages:

- **Environmental Protection**: Recycling reduces the amount of plastic waste in landfills and oceans, protecting ecosystems and wildlife.

- **Resource Conservation**: By recycling EVA, we conserve fossil fuels and other natural resources needed for new plastic production.

- **Energy Savings**: Recycling processes generally consume less energy than producing new materials from raw resources.

- **Job Creation**: The recycling industry contributes to local economies through job creation in collection, processing, and manufacturing sectors.

5. How to Choose the Right EVA Recycling Service

Selecting the right EVA recycling service is essential for maximizing the benefits of recycling. Consider the following factors when making your choice:

- **Location**: Look for recycling facilities near your location to minimize transportation costs and emissions.

- **Service Offerings**: Assess whether the service provides mechanical, chemical, or energy recovery options based on your needs.

- **Certifications**: Choose a recycling service that adheres to industry standards and has the necessary certifications to ensure proper recycling practices.

- **Reputation**: Research the company's track record and customer feedback to gauge reliability and effectiveness.

6. The EVA Recycling Process Explained

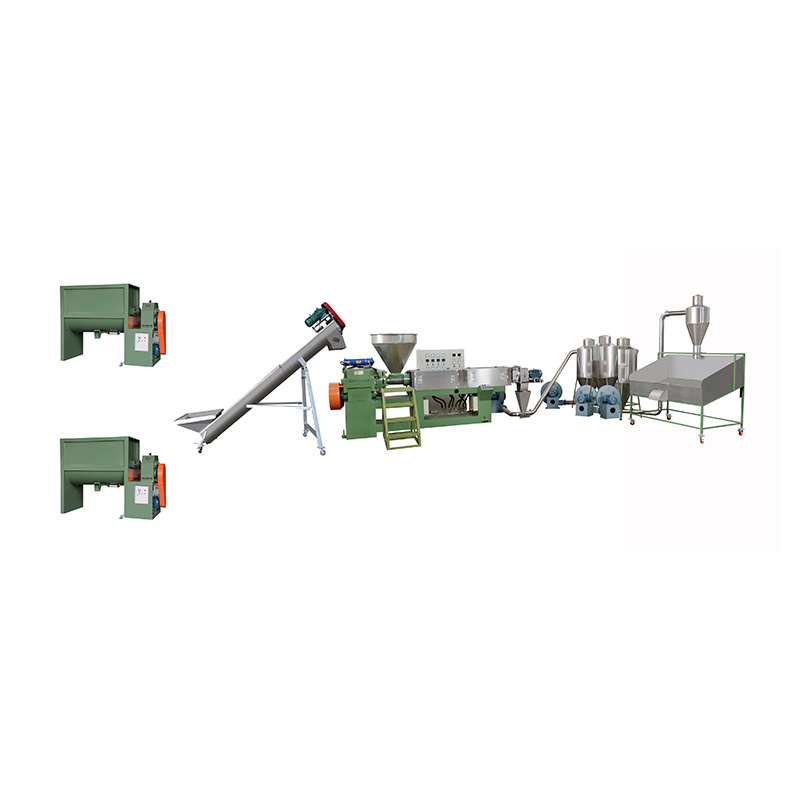

The recycling process for EVA plastic can vary based on the method used. Here's a breakdown of the typical steps involved in mechanical recycling:

1. **Collection**: Used EVA products are collected from various sources, including households, businesses, and manufacturing facilities.

2. **Sorting**: The collected materials are sorted to remove contaminants and non-EVA plastics, ensuring purity in the recycling process.

3. **Cleaning**: The sorted materials undergo cleaning to eliminate residual dirt, adhesives, or other foreign substances.

4. **Shredding**: Cleaned EVA is shredded into smaller pieces, making it easier to melt and mold.

5. **Melting and Extrusion**: The shredded EVA is melted and extruded into new shapes, like pellets or sheets, ready for manufacturing.

For chemical recycling, the process will involve breaking down the EVA into its monomer components before they are reassembled into new products.

7. Challenges in EVA Plastic Recycling

While EVA plastic recycling has several advantages, it also faces challenges. Some of the prominent issues include:

- **Contamination**: Contaminants can hinder the recycling process, making it essential to ensure that EVA waste is clean and sorted properly.

- **Limited Market Demand**: The demand for recycled EVA products may not be as high as that for virgin materials, affecting the economic viability of recycling initiatives.

- **Technical Limitations**: Not all EVA products are suitable for recycling, especially those mixed with other materials, which can complicate the recycling process.

8. Future of EVA Plastic Recycling

The future of EVA plastic recycling looks promising as technology continues to advance. Innovations in chemical recycling and improved sorting technologies may enhance the efficiency and effectiveness of recycling processes. Additionally, increasing consumer awareness and demand for sustainable practices encourage businesses to adopt recycling initiatives.

Moreover, collaborations between industries, governments, and research institutions can lead to the development of better recycling infrastructures and systems, propelling the movement towards a circular economy.

9. Frequently Asked Questions (FAQs)

What is EVA plastic commonly used for?

EVA plastic is commonly used in products like footwear, sports equipment, packaging materials, and foam padding due to its flexibility and durability.

Can EVA plastic be recycled multiple times?

Yes, EVA plastic can be recycled multiple times, although mechanical recycling may reduce its quality over time. Chemical recycling can help regenerate high-quality EVA materials.

How can I find a local EVA recycling service?

You can find a local EVA recycling service by searching online directories, contacting waste management companies, or checking with municipal waste services.

What are the environmental benefits of recycling EVA plastic?

Recycling EVA plastic reduces landfill waste, conserves natural resources, saves energy, and lowers carbon emissions, contributing to environmental protection.

Is chemical recycling better than mechanical recycling for EVA?

Both methods have their advantages. Chemical recycling is beneficial for contaminated or mixed materials, while mechanical recycling is more energy-efficient for clean EVA products.

10. Conclusion

Understanding the different types of EVA plastic recycling services is crucial for promoting sustainable practices. By choosing the right recycling service, we can contribute to a circular economy, reduce environmental impact, and ensure the longevity of valuable resources. As technologies continue to evolve, the recycling process for EVA plastic will become more efficient, paving the way for a cleaner, greener future.

Related Blog