Exploring the Landscape of PU Waste Plastic Recycling Machine Brands

Release Time:

Jun 03,2025

The rise in environmental awareness has led to a significant push towards recycling, particularly in the realm of polyurethane (PU) waste. PU waste, often generated from various industrial processes and consumer products, poses considerable challenges due to its durability and resistance to degradation. In response, the market offers a range of PU waste plastic recycling machines designed to effic

The rise in environmental awareness has led to a significant push towards recycling, particularly in the realm of polyurethane (PU) waste. PU waste, often generated from various industrial processes and consumer products, poses considerable challenges due to its durability and resistance to degradation. In response, the market offers a range of PU waste plastic recycling machines designed to efficiently process and convert waste into reusable materials.

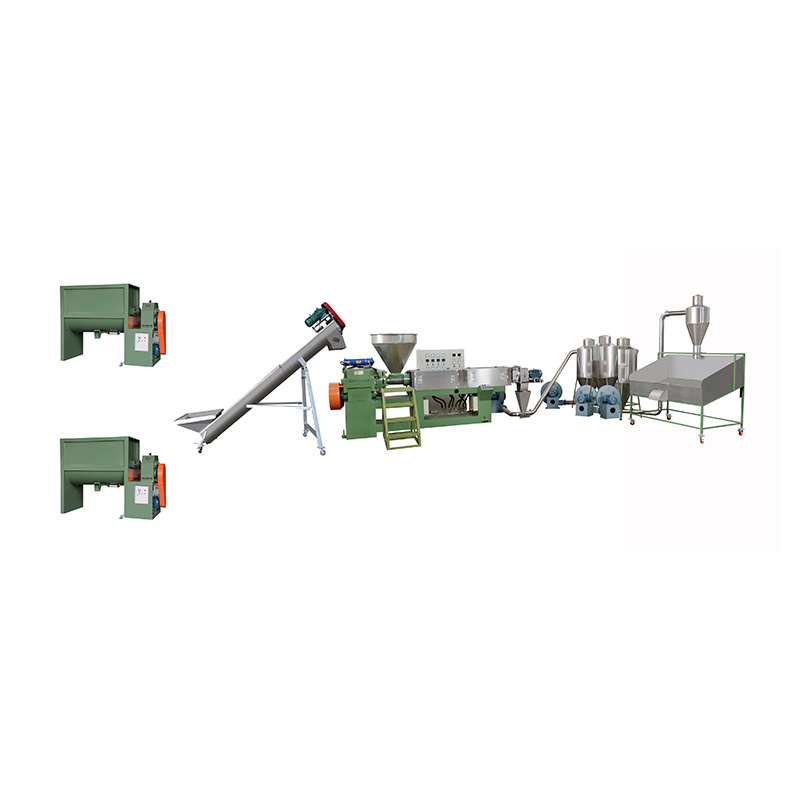

When considering PU waste plastic recycling machine brands, it is crucial to understand the core functionalities these machines provide. Most units are equipped with advanced technologies that facilitate the breakdown of PU materials through processes such as grinding, melting, and reforming. This not only helps in reducing landfill waste but also contributes to creating a circular economy where materials are repurposed rather than discarded.

Additionally, the choice of a machine can significantly influence the efficiency of your recycling operations. Factors such as machine capacity, energy consumption, and ease of maintenance should be taken into account. A machine that offers high throughput while minimizing energy costs can lead to substantial long-term savings. Moreover, the availability of technical support and service options from the manufacturer is an essential consideration for ensuring operational continuity.

Another important aspect is the innovation in recycling technologies. Many leading PU waste plastic recycling machine brands are incorporating automation and smart technology, allowing for real-time monitoring and optimization of the recycling process. This not only enhances efficiency but also provides valuable data that can inform operational improvements and compliance with environmental regulations.

Furthermore, as the recycling landscape continues to evolve, staying abreast of emerging trends and advancements in the industry is vital. This includes understanding the regulatory environment surrounding waste management and recycling, as compliance can significantly impact operational practices. Engaging with industry forums and attending trade shows can provide insights into new technologies and best practices shared by peers.

In conclusion, navigating the diverse array of PU waste plastic recycling machine brands requires a thorough understanding of both the technical and operational aspects of these machines. By prioritizing efficiency, technological innovation, and support services, professionals in the mechanical repair and installation sector can make informed decisions that enhance their recycling capabilities and contribute positively to environmental sustainability. As we move towards a more eco-conscious future, investing in the right recycling technology becomes not just a business choice but a commitment to a sustainable planet.

When considering PU waste plastic recycling machine brands, it is crucial to understand the core functionalities these machines provide. Most units are equipped with advanced technologies that facilitate the breakdown of PU materials through processes such as grinding, melting, and reforming. This not only helps in reducing landfill waste but also contributes to creating a circular economy where materials are repurposed rather than discarded.

Additionally, the choice of a machine can significantly influence the efficiency of your recycling operations. Factors such as machine capacity, energy consumption, and ease of maintenance should be taken into account. A machine that offers high throughput while minimizing energy costs can lead to substantial long-term savings. Moreover, the availability of technical support and service options from the manufacturer is an essential consideration for ensuring operational continuity.

Another important aspect is the innovation in recycling technologies. Many leading PU waste plastic recycling machine brands are incorporating automation and smart technology, allowing for real-time monitoring and optimization of the recycling process. This not only enhances efficiency but also provides valuable data that can inform operational improvements and compliance with environmental regulations.

Furthermore, as the recycling landscape continues to evolve, staying abreast of emerging trends and advancements in the industry is vital. This includes understanding the regulatory environment surrounding waste management and recycling, as compliance can significantly impact operational practices. Engaging with industry forums and attending trade shows can provide insights into new technologies and best practices shared by peers.

In conclusion, navigating the diverse array of PU waste plastic recycling machine brands requires a thorough understanding of both the technical and operational aspects of these machines. By prioritizing efficiency, technological innovation, and support services, professionals in the mechanical repair and installation sector can make informed decisions that enhance their recycling capabilities and contribute positively to environmental sustainability. As we move towards a more eco-conscious future, investing in the right recycling technology becomes not just a business choice but a commitment to a sustainable planet.

Related Blog