Understanding Waste Plastic Crusher Machines: A Vital Tool for Sustainable Recycling

Release Time:

Jan 15,2026

Waste plastic crusher machines are integral to the recycling process, particularly regarding plastic waste. As environmental concerns grow, the importance of efficient waste management systems becomes increasingly evident. These machines are designed to break down plastic materials into smaller pieces, making them easier to process and recycle. This article will explore the workings, benefits, and

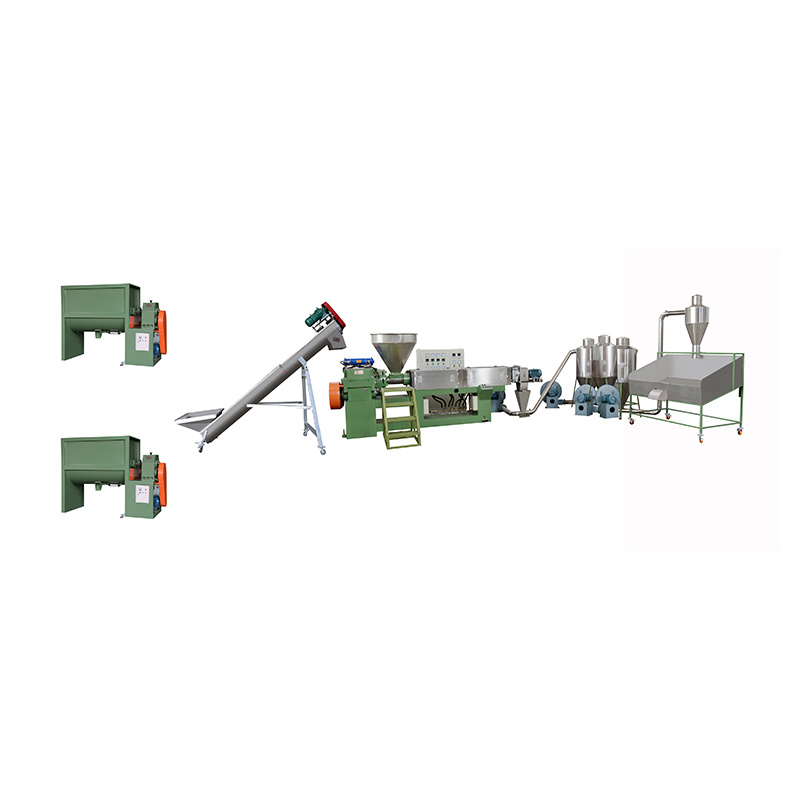

Waste plastic crusher machines are integral to the recycling process, particularly regarding plastic waste. As environmental concerns grow, the importance of efficient waste management systems becomes increasingly evident. These machines are designed to break down plastic materials into smaller pieces, making them easier to process and recycle. This article will explore the workings, benefits, and significance of waste plastic crusher machines in promoting sustainability and efficient waste management.

The primary function of a waste plastic crusher machine is to take various types of plastic waste, including bottles, containers, and packaging materials, and shred them into manageable pieces. This process not only reduces the volume of waste but also facilitates the efficient sorting and recycling of plastics. By converting large plastic items into granules or chips, these machines enable recycling facilities to handle the material more effectively, resulting in a more streamlined recycling process.

One of the significant advantages of waste plastic crusher machines is their ability to enhance recycling efficiency. When plastic waste is reduced to smaller sizes, it can be more easily melted down and repurposed into new products. This not only conserves resources but also minimizes the amount of plastic that ends up in landfills or the environment. Additionally, the recycling of plastics helps reduce greenhouse gas emissions, as it generally requires less energy compared to producing new plastic from raw materials.

Moreover, investing in a waste plastic crusher machine can lead to cost savings in the long run. By reducing the volume of plastic waste, businesses can lower disposal costs and potentially generate revenue from selling recycled materials. This aligns with the growing trend of circular economy practices, where products and materials are reused, remanufactured, and recycled to create a closed-loop system that minimizes waste.

It's important to note that while waste plastic crusher machines are highly effective, proper maintenance and technical support are crucial for optimal performance. Regular servicing ensures that the machines operate efficiently and can handle the demands of high-volume plastic waste processing. Additionally, understanding the specific types of plastics that can be processed and the machine's operational guidelines can significantly enhance its effectiveness.

In summary, waste plastic crusher machines are vital tools in the effort to combat plastic pollution and promote sustainable waste management practices. By breaking down plastic waste into smaller, usable forms, these machines facilitate recycling and contribute to environmental conservation. For businesses looking to improve their waste management processes, investing in a waste plastic crusher machine could be a strategic move towards achieving sustainability goals and enhancing operational efficiency.

The primary function of a waste plastic crusher machine is to take various types of plastic waste, including bottles, containers, and packaging materials, and shred them into manageable pieces. This process not only reduces the volume of waste but also facilitates the efficient sorting and recycling of plastics. By converting large plastic items into granules or chips, these machines enable recycling facilities to handle the material more effectively, resulting in a more streamlined recycling process.

One of the significant advantages of waste plastic crusher machines is their ability to enhance recycling efficiency. When plastic waste is reduced to smaller sizes, it can be more easily melted down and repurposed into new products. This not only conserves resources but also minimizes the amount of plastic that ends up in landfills or the environment. Additionally, the recycling of plastics helps reduce greenhouse gas emissions, as it generally requires less energy compared to producing new plastic from raw materials.

Moreover, investing in a waste plastic crusher machine can lead to cost savings in the long run. By reducing the volume of plastic waste, businesses can lower disposal costs and potentially generate revenue from selling recycled materials. This aligns with the growing trend of circular economy practices, where products and materials are reused, remanufactured, and recycled to create a closed-loop system that minimizes waste.

It's important to note that while waste plastic crusher machines are highly effective, proper maintenance and technical support are crucial for optimal performance. Regular servicing ensures that the machines operate efficiently and can handle the demands of high-volume plastic waste processing. Additionally, understanding the specific types of plastics that can be processed and the machine's operational guidelines can significantly enhance its effectiveness.

In summary, waste plastic crusher machines are vital tools in the effort to combat plastic pollution and promote sustainable waste management practices. By breaking down plastic waste into smaller, usable forms, these machines facilitate recycling and contribute to environmental conservation. For businesses looking to improve their waste management processes, investing in a waste plastic crusher machine could be a strategic move towards achieving sustainability goals and enhancing operational efficiency.

Related Blog