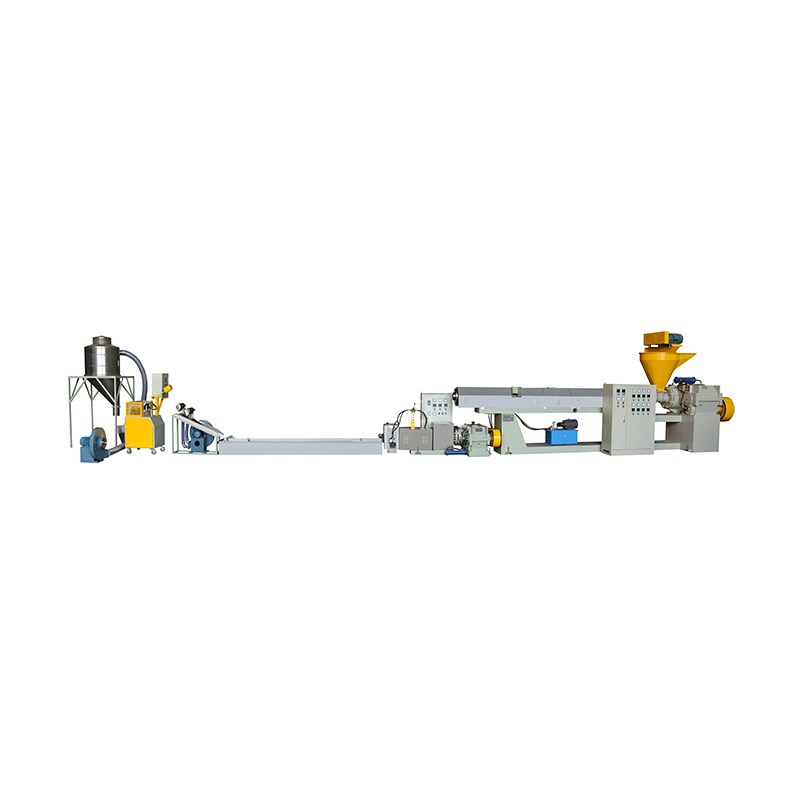

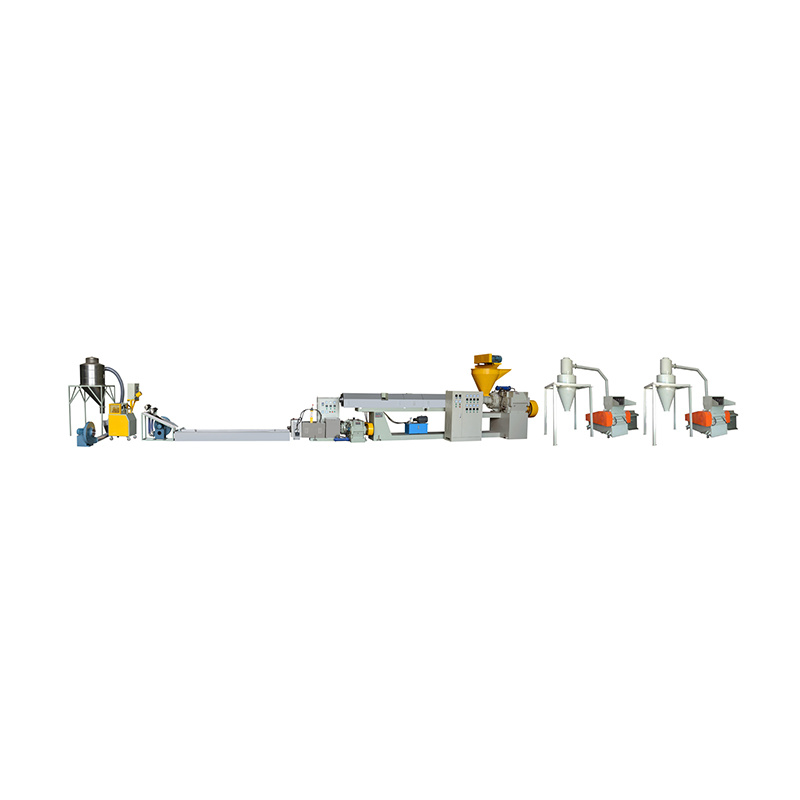

EVA INJECTION SHOE SOLE WASTE / EVA MOLD SHOE SOLES WASTE PLASTIC RECYCLING MACHINE

Provide a variety of machine capacity. Please consult relevant details before ordering the machine. The following information is for reference only.

- Commodity name: EVA INJECTION SHOE SOLE WASTE / EVA MOLD SHOE SOLES WASTE PLASTIC RECYCLING MACHINE

Product Description

Are you looking for a high-quality, cost-effective solution for recycling waste plastic into durable EVA mold shoe soles? Look no further! Our Durable EVA Mold Shoe Soles Waste Plastic Recycling Machine is the perfect choice for companies aiming to reduce waste while creating sustainable products.

Manufactured in China, our plastic recycling machine is designed to transform waste plastic materials into high-quality EVA shoe soles, making it an excellent investment for shoe manufacturers, recycling companies, and factories. With wholesale prices directly from the China supplier, we ensure the most competitive rates available.

Our EVA Mold Shoe Soles Waste Plastic Recycling Machine is the ideal choice for businesses looking to scale up their recycling processes and reduce production costs. Whether you're looking to buy in bulk or just get started with small-scale production, we offer flexible options that suit your needs.

Machine Details

EVA INJECTION SHOE SOLE WASTE / EVA MOLD SHOE SOLES WASTE PLASTIC RECYCLING MACHINE | ||

Number | Product | Remark |

1 | Belt loader | Width:600mm Length: 2500mm Motor power: 1.5KW |

2 | Crusher | Type: 800 Fixed knife: 4 pcs Rotary knife: 6 pcs Motor power: 75KW Contactor brand: TAIAN Equipped with suction system Output: 700-900kg/hr |

3 | Screw loader | Motor power: 3KW Material contact surface: stainless steel |

Main extruder | ||

4 | Screw and Barrel | Screw diameter:140 mm Barrel length: 4500mm Screw material: 38CrMoAIA nitrogen treatment and three parts alloy powder spray-spread Barrel material: 38CrMoAIA nitrogen treatment and the feeding chamber opening of the barrel with alloy powder spray-spread |

5 | Gear Box | Model: 375 |

6 | Motor | Motor power: 75KW-4P Speed controlled by Delta(350V-480V,50HZ-60HZ) inverter |

7 | Control Box | 4 sets electromagnetic heating Power: 30KW/Set |

8 | Die Head | Round die head |

9 | Force Feeder | Motor power: 5.5KW Motor with Delta inverter(350V-480V,50HZ-60HZ) control |

Baby extruder 1 | ||

10 | Screw and Barrel | Screw diameter:155 mm Screw material: 38CrMoAIA nitrogen treatment Barrel length: 1400mm Barrel material: 38CrMoAIA nitrogen treatment |

11 | Gear Box | Model: 250 |

12 | Motor | Motor power: 30KW-4P Speed controlled by Delta(350V-480V,50HZ-60HZ) inverter |

13 | Control Box | 4 sets Controller Brand: SKG Contactor Brand:LS |

14 | Die Head | Hydraulicdoubleplates Screen size: 220mm Screen sieve changer by hydraulic controlling system |

15 | Feeder | Square feeder With heating system |

Baby extruder 2 | ||

16 | Screw and Barrel | Screw diameter:125 mm Screw material: 38CrMoAIA nitrogen treatment Barrel length: 1200mm Barrel material: 38CrMoAIA nitrogen treatment |

17 | Gear Box | Model: 200 |

18 | Motor | Motor power:18.5KW-4P Speed controlled by Delta(350V-480V,50HZ-60HZ) inverter |

19 | Control Box | 4 sets Controller Brand: SKG Contactor Brand:LS |

20 | Die Head | Hydraulicsingleplates Screen size: 220mm Screen sieve changer by hydraulic controlling system |

21 | Feeder | Square feeder With heating system |

Auxiliary part | ||

22 | Water tank | Length:8000mm Material:#304 stainless steel |

23 | Dryer | One set Motor power:2.2KW |

24 | Cutter | Type 300PLUS Motor power: 7.5KW Contactor Brand:LS Speed controlled by Delta(350V-480V,50HZ-60HZ) inverter |

25 | Silo | Motor power of blower: 3KW Capacity:250KG Material: stainless steel |

26 | Output | 4000-5000kg/24hr |

Payment Terms

- 30% deposit by T/T

- 70% by T/T before delivery and after inspection

Delivery Time

45-50 working days since the date of receiving deposit

Warranty Period

12 months since date of bill of lading

Laite Brothers Plastic Machinery CO., LTD will charge the buyer cost of spare beyond one year and provide long-term technical guide

Our product range includes: Plastic Recycling Pelletizers for Crosslinked PE Foam/EVA Foam waste, EVA shoe soles waste, PVC waste and other plastics waste, Agglomerators for EVA, PVC,TPR, Crusher and Blenders.

Key words:

EVA INJECTION SHOE SOLE WASTE / EVA MOLD SHOE SOLES WASTE PLASTIC RECYCLING MACHINE