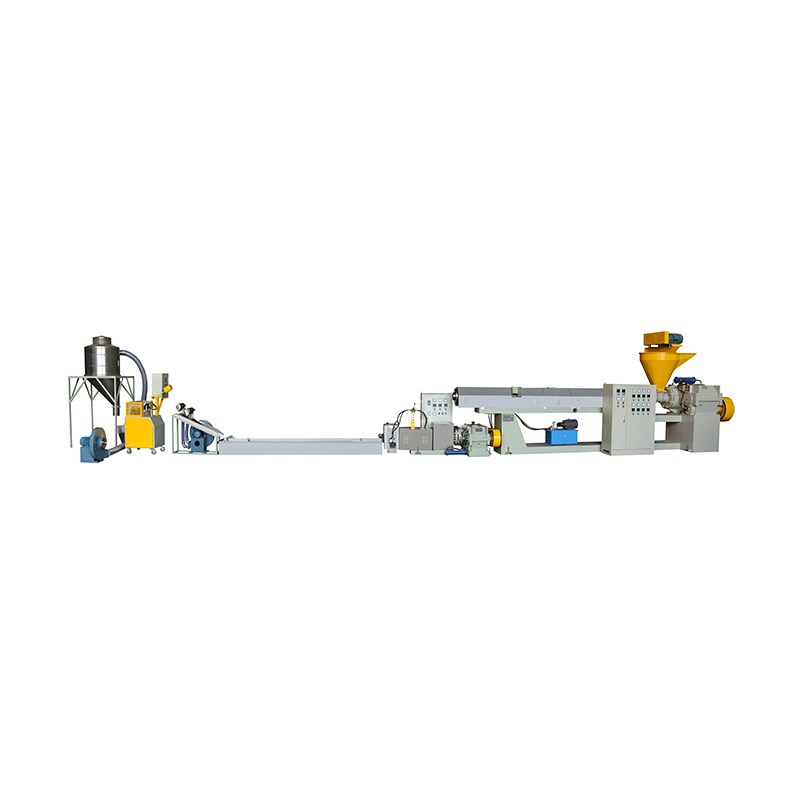

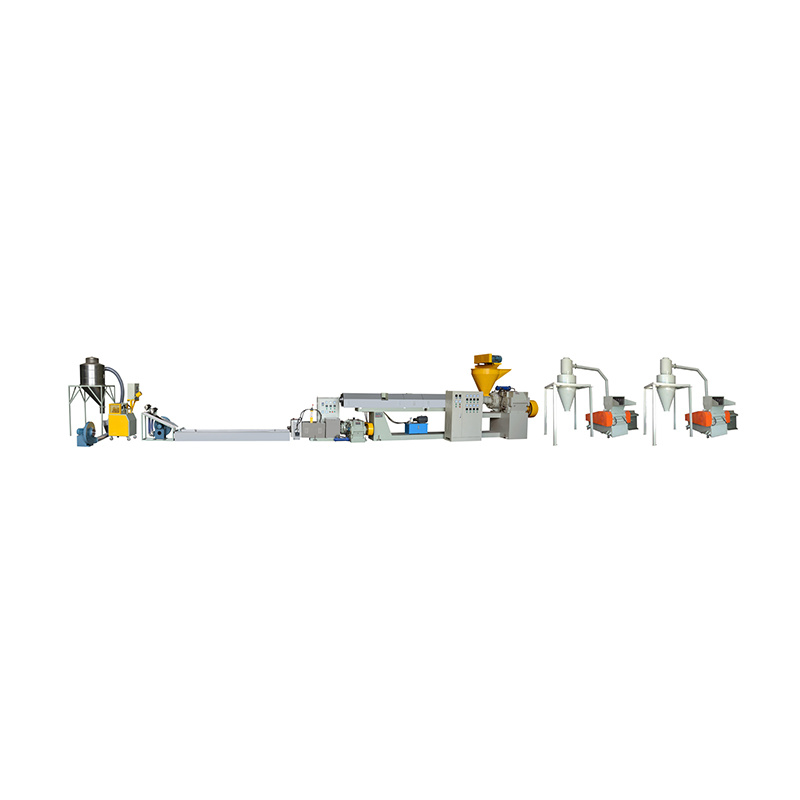

250-330KG PP / PE film three - stage plastic recycling machine 160

Provide a variety of machine capacity. Please consult relevant details before ordering the machine. The following information is for reference only.

- Commodity name: 250-330KG PP / PE film three - stage plastic recycling machine 160

Product Description

Machine Details

PP / PE plastic recycling machine | ||

Number | Product |

|

1 | Belt loader | Motor power: 1.5KW Belt width: 500mm Height: 2250mm |

Main extruder | ||

2 | Screw and barrel | Screw diameter:160 mm Barrel length: 4000mm Screw material: 38CrMoAIA nitrogen treatment and three parts alloy powder spray-spread Barrel material: 38CrMoAIA nitrogen treatment and the feeding chamber opening of the barrel with alloy powder spray-spread Barrel equipped with two vents |

3 | Gear box | Model: 375 |

4 | Motor | Motor power: 75KW-4P Speed controlled by Delta(350V-480V,50HZ-60HZ) inverter |

5 | Control box | 4 sets electromagnetic heating Motor power: 40KW/Set |

6 | Die Head |

Round die head

|

7 | Force feeder | Motor power: 5.5KW Speed controlled by Delta(350V-480V,50HZ-60HZ) inverter |

子机1 Baby extruder 1 | ||

8 | Screw and barrel | Screw diameter:155 mm Barrel length: 1400mm Screw material: 38CrMoAIA nitrogen treatment Barrel material: 38CrMoAIA nitrogen treatment |

9 | Gear box | Model: 250 |

10 | Motor | Motor power: 37KW-4P Speed controlled by Delta(350V-480V,50HZ-60HZ) inverter |

11 |

Control box | 4 sets Controller Brand: SKG Contactor Brand:LS

|

12 |

Die Head | Hydraulic double plates Screen size:300mm Screen sieve changer by hydraulic controlling system |

13 | Feeder | Square feeder with heating system

|

Baby extruder 2 | ||

14 | Screw and barrel | Screw diameter:135 mm Barrel length: 1400mm Screw material: 38CrMoAIA nitrogen treatment Barrel material: 38CrMoAIA nitrogen treatment |

15 | Gear box | Model: 225 |

16 | Motor | Motor power: 30KW-4P Speed controlled by Delta(350V-480V,50HZ-60HZ) inverter |

17 | Control box | 4 sets Controller Brand: SKG Contactor Brand:LS |

18 | Die Head | Hydraulic single plates Screen size:300mm Screen sieve changer by hydraulic controlling system |

19 | Feeder | Square feeder with heating system |

Auxiliary parts | ||

20 | Water tank | Length: 3500mm(#304stainless steel) |

21 | Dryer | One set Motor power:2.2KW |

22 | Cutter | Type 300PLUS Motor power: 5.5KW Contactor Brand:LS Speed controlled by Delta(350V-480V,50HZ-60HZ) inverter |

23 | Silo | Capacity:250KG Material: stainless steel Motor power: 3KW |

24 | Output | PP: 200-300kg/hr PE: 250-330kg/hr |

Payment terms

- 30% deposit by T/T

- 70% by T/T before delivery and after inspection

Delivery time

40-45 working days since the date of receiving deposit

Warranty period

12 months since date of bill of lading

Laite Brothers Plastic Machinery CO., LTD will charge the buyer cost of spare beyond one year and provide long-term technical guide

Our product range includes: Plastic Recycling Pelletizers for Crosslinked PE Foam/EVA Foam waste, EVA shoe soles waste, PVC waste and other plastics waste, Agglomerators for EVA, PVC,TPR, Crusher and Blenders.

Key words:

250-330KG PP / PE film three - stage plastic recycling machine 160